Summary of Contents for Brother DreamWeaver„ VQ3000

-

Page 1: Sewing Machine

Operation Manual Sewing Machine Product Code: 882-D00 Be sure to read this document before using the machine. We recommend that you keep this document nearby for future reference. - Page 2 TRADEMARKS IMPORTANT: READ BEFORE DOWNLOADING, COPYING, INSTALLING OR USING. By downloading, copying, installing or using the software you agree to this license. If you do not agree to this license, do not download, install, copy or use the software. Intel License Agreement For Open Source Computer Vision Library Copyright ©...

-

Page 3: Introduction

INTRODUCTION INTRODUCTION Thank you for purchasing this machine. Before using this machine, carefully read the “IMPORTANT SAFETY INSTRUCTIONS”, and then study this manual for the correct operation of the various functions. In addition, after you have finished reading this manual, store it where it can quickly be accessed for future reference. - Page 4 IMPORTANT SAFETY INSTRUCTIONS Always keep your work area clear: • Never operate the machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the build up of lint, dust, and loose cloth. •...

- Page 5 IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS This machine is intended for household use. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Page 6 IMPORTANT SAFETY INSTRUCTIONS Federal Communications Commission (FCC) Declaration of Conformity (For USA Only) Responsible Party: Brother International Corporation 100 Somerset Corporate Boulevard Bridgewater, NJ 08807-0911 USA TEL : (908) 704-1700 declares that the product Product Name: Brother Sewing Machine Model Number: VQ3000 This device complies with Part 15 of the FCC Rules.

- Page 7 IMPORTANT SAFETY INSTRUCTIONS Laser Notices (For U.S.A. only) Laser Safety This sewing machine is certified as a Class 1 laser product under the U.S. Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968. This means that the sewing machine does not produce hazardous laser radiation.

- Page 8 IMPORTANT SAFETY INSTRUCTIONS Laser Notices (For countries except U.S.A.) IEC 60825-1 Specification This sewing machine is a Class 1 laser product as defined in IEC 60825-1:2007 specifications. The laser beam emitted by the laser unit installed in this machine is restricted to an output at a safe level. However, the machine contains 7-milliwat, 650-660nanometer wavelength, 6-12 degree at parallel divergence angle, 24-34 degree at perpendicular divergence angle, InGaAlP laser diodes.

-

Page 9: Outstanding Features

OUTSTANDING FEATURES OUTSTANDING FEATURES Setting Laser Guideline Marker Expanding Your Creativity with as a Guide to Sew Dual Feed Foot The guideline marker shows the sewing position. You can adjust the sewing position by moving the guideline marker while checking the guideline marker on the fabric. -

Page 10: What You Can Do With This Machine

WHAT YOU CAN DO WITH THIS MACHINE WHAT YOU CAN DO WITH THIS MACHINE Basic operations After purchasing your machine, be sure to read this section first. This section provides details on the initial setup procedures as well as descriptions of this machine’s more useful functions. Chapter 1 Chapter 2 Getting Ready... -

Page 11: Table Of Contents

CONTENTS CONTENTS TRADEMARKS Specifying the Needle Drop Position With the Sensor Pen..66 Using the Sensor Pen to Specify the Stitching Width INTRODUCTION..........1 and Stitch Position..............67 IMPORTANT SAFETY INSTRUCTIONS ....1 Using the Sensor Pen to Specify the Sewing End Point..69 OUTSTANDING FEATURES ......... - Page 12 CONTENTS Chapter3 Character/Decorative Stitches 76 Adjusting the Brightness of the Screen Display..... 18 Touch Panel is Malfunctioning ..........18 SELECTING STITCH PATTERNS......77 TROUBLESHOOTING ........19 Selecting Decorative Stitch Patterns/7mm Decorative Stitch Frequent troubleshooting topics........... 19 Patterns/Satin Stitch Patterns/7mm Satin Stitch Upper thread tightened up...........

-

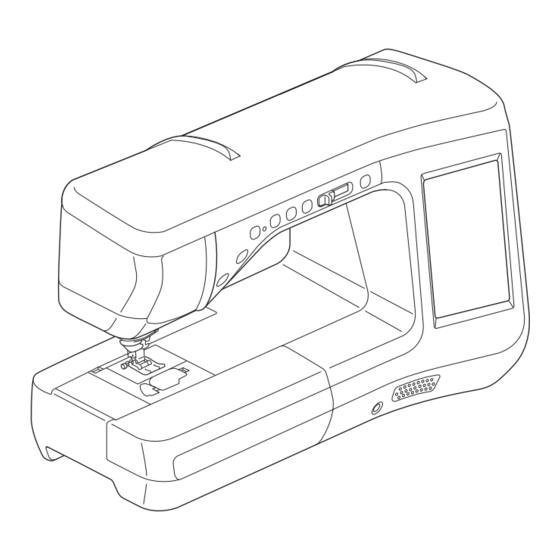

Page 13: Names Of Machine Parts And Their Functions

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS NAMES OF MACHINE PARTS AND THEIR FUNCTIONS The names of the various parts of the sewing machine and their functions are described below. Before using the sewing machine, carefully read these descriptions to learn the names of the machine parts. Machine ■... -

Page 14: Needle And Presser Foot Section

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS Needle and Presser Foot Section Measurements on the needle plate, bobbin cover (with mark) and needle plate cover The measurements on the bobbin cover are references for patterns with a middle (center) needle position. The measurements on the needle plate and the needle plate cover are references for stitches with a left needle position. -

Page 15: Operation Buttons

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS Operation Buttons Using the Flat Bed Attachment Pull the top of the flat bed attachment to open the accessory compartment. a “Start/Stop” button Press this button and the machine will sew a few stitches at a slow speed and then begin sewing at the speed set by the sewing speed controller. -

Page 16: Included Accessories

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS Included Accessories 75/11 2 needles 90/14 2 needles 2.0/11 needle 90/14 2 needles: Ball point needle (gold colored) *Included accessories vary depending on the countries or regions. B-14... - Page 17 NAMES OF MACHINE PARTS AND THEIR FUNCTIONS Part Code Part Code Part Name Part Name Americas Others Americas Others 50 MY CUSTOM STITCH CD* XE8901-001 Zigzag foot “J” (on machine) XF3022-001 Monogramming foot “N” X53840-351 Memo Overcasting foot “G” XC3098-051 •...

-

Page 18: Options

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS Options The following are available as optional accessories to be purchased separately from your authorized Brother dealer. Part Code Part Name Americas Others Multi-function foot controller SAMFFC MFFC1: (U.S.A.) XF4159-001 SAMFFCC MFFC1OC: (Canada) XF4471-001 (Australia) 10 spool stand... -

Page 19: Basic Operations

Basic operations This section provides details on the initial setup procedures as well as descriptions of this machine’s more useful functions. Page number starts with “B” in this section. Chapter1 Getting Ready ............B-18 Chapter2 Sensor Functions ...........B-58... - Page 20 BBasic operations Chapter Getting Ready TURNING THE MACHINE ON/OFF ......19 Setting Your Machine for the First Time ........20 LCD SCREEN............22 ■ Utility Stitch Screen ..............22 ■ Key Functions................23 Using the Machine Setting Mode Key ........25 ■ Selecting the “Eco Mode” or “Shutoff Support Mode”..... 28 ■...

-

Page 21: Turning The Machine On/Off

TURNING THE MACHINE ON/OFF TURNING THE MACHINE ON/OFF WARNING • Use only regular household electricity for the power source. Using other power sources may result in fire, electric shock, or damage to the machine. • Make sure that the plugs on the power cord are firmly inserted into the electrical outlet and the power cord receptacle on the machine. -

Page 22: Setting Your Machine For The First Time

TURNING THE MACHINE ON/OFF Insert the power supply cord into the power Turn the main power switch to “O” to turn cord receptacle, then insert the plug into a off the machine. wall outlet. Memo • If the machine is turned off in the middle of sewing in the “Sewing”... - Page 23 TURNING THE MACHINE ON/OFF Press to set time/date. a Press to display the time on the screen. b Set the year (YYYY), month (MM) and date (DD). c Select whether 24h or 12h setting to display. d Set the current time. Press to start using your machine.

-

Page 24: Lcd Screen

LCD SCREEN LCD SCREEN CAUTION • Only touch the screen with your finger or the included touch pen. Do not use a sharp pencil, screwdriver, or other hard or sharp object. It is not necessary to press hard on the screen. Pressing too hard or using a sharp object may damage the screen. -

Page 25: Key Functions

LCD SCREEN Display Key Name Explanation Page Scroll key – Press , to move one page at a time, or touch anywhere on the bar to jump ahead for additional pages of stitches. All key functions of the LCD are explained in the following “Key Functions”. ■... - Page 26 LCD SCREEN Display Key Name Explanation Page Presser foot/Needle Press this key before changing the needle, the presser foot, etc. This key locks B-49 to exchange key all key and button functions to prevent operation of the machine. B-51 Sewing machine help Press this key to see explanations on how to use the machine.

-

Page 27: Using The Machine Setting Mode Key

LCD SCREEN Using the Machine Setting Mode Key Press to change the default machine settings (needle stop position, opening display, etc.). Memo • Press next to the page numbers, to display a different settings screen. a Select whether to use the sewing speed controller to determine the zigzag width (see page S-39). b Make adjustments to character or decorative stitch patterns (see page S-82). - Page 28 LCD SCREEN a Select the needle stop position (the needle position when the machine is not operating) to be up or down. Select the down position when using the pivot key. (see page S-15) b Select the operation of the “Needle Position – Stitch Placement” button from the following two sequences (see page S-18).

- Page 29 LCD SCREEN a Change the brightness of the needle area and work area lights. b Change the screen display brightness (see page A-18). c Calibrate the sensor function (see page B-62). d Display the service count which is a reminder to take your machine in for regular servicing. (Contact your authorized dealer for details.) e Display the total number of stitches sewn on this machine.

-

Page 30: Selecting The "Eco Mode" Or "Shutoff Support Mode

LCD SCREEN ■ Selecting the “Eco Mode” or ■ Changing the Pointer Shape When a “Shutoff Support Mode” USB Mouse Is Used You can save the machine power by setting the eco In the settings screen, the shape can be selected for mode or the shutoff support mode. -

Page 31: Choosing The Display Language

LCD SCREEN ■ Choosing the Display Language Remove the USB media, and then for future reference, check the saved image using a Press computer. → The settings screen appears. The files for Settings screen images are saved with the name “S##.BMP”. Display page 5 of the settings screen. -

Page 32: Using The Sewing Machine Help Key

LCD SCREEN Using the Sewing Machine Help Key Press to open the sewing machine help screen. Three functions are available from the screen shown below. a Press this key to see explanation for upper threading, winding the bobbin, changing the presser foot, and how to use the machine (see page B-31). -

Page 33: Using The Operation Guide Function

LCD SCREEN Using the Operation Guide Function Press to open the screen shown below. Five categories are displayed at the top of the screen. Press a key to see more information about that category. displays information about displays information about displays information about the main parts of the machine and their the operation buttons. -

Page 34: Using The Sewing Guide Function

LCD SCREEN Example: Displaying information about Using the Sewing Guide Function upper threading Press The sewing guide function can be used to select patterns from the Utility Stitch screen. Press Use this function when you are not sure which stitch to use for your application, or to get advice about sewing particular stitches. -

Page 35: Using The Pattern Explanation Function

LCD SCREEN Press Using the Pattern Explanation Function If you want to know more about the uses of a stitch pattern, select the pattern and press then to see an explanation of the stitch selection. Note • Descriptions are displayed for each pattern in the Utility Stitch screen. -

Page 36: Lower Threading

LOWER THREADING LOWER THREADING ■ Using the Supplemental Spool Pin Winding the Bobbin With this machine, you can wind the bobbin without unthreading the machine. While using the main spool pin to sew, you can conveniently wind → → → Press the bobbin using the supplemental spool pin. - Page 37 LOWER THREADING Set the supplemental spool pin in the “up” Memo position. • When sewing with fine, cross-wound thread, use the small spool cap, and leave a small space between the cap and the thread spool. a Spool cap (small) a Supplemental spool pin b Thread spool (cross-wound thread) Place the spool of thread on the...

- Page 38 LOWER THREADING Pass the thread around the pre-tension disk Pass the end of the thread through the guide making sure that the thread is under the slit in the bobbin winder seat, and pull the pre-tension disk. thread to the right to cut the thread with the cutter.

-

Page 39: Setting The Bobbin

LOWER THREADING Press Cut the thread with scissors and remove the bobbin. → Bobbin winding starts automatically. The bobbin stops rotating when bobbin winding is completed. The bobbin winding switch will automatically return to its original position. Note • changes to while the bobbin Memo is winding. -

Page 40: Untangling Thread From Beneath The Bobbin Winder Seat

LOWER THREADING Turn the main power to ON and open the Pass the thread through the thread guide. top cover. Align the groove in the bobbin with the spring on the bobbin winder shaft, and set the bobbin on the shaft. a Thread guide Pass the thread around the pre-tension disk making sure that the thread is under the... -

Page 41: Setting The Bobbin

LOWER THREADING If the thread becomes tangled under the Setting the Bobbin bobbin winder seat, press once to stop the bobbin winding. → → → Press → in this order to display a video example of the operation on the LCD (see page B-33). - Page 42 LOWER THREADING Slide the bobbin cover latch to the right. While lightly holding down bobbin with your right hand as shown, guide the thread through the slit (a and b). At this time, check that the bobbin easily rotates counterclockwise. Then, pull the thread toward you to cut it with the cutter (c).

-

Page 43: Pulling Up The Bobbin Thread

LOWER THREADING Insert the tab in the lower-left corner of the Press the “Needle Position” button to raise bobbin cover (1), and then lightly press the needle. down on the right side to close the cover Gently pull the upper thread. A loop of the (2). -

Page 44: Upper Threading

UPPER THREADING UPPER THREADING Turn the main power to ON. Upper Threading Press the “Presser Foot Lifter” button to → → → Press raise the presser foot. → in this order to display a video example of the operation on the LCD (see page B-33). - Page 45 UPPER THREADING Pivot the spool pin so that it angles upward. Set the thread spool on the spool pin so that Memo • When sewing with fine, cross-wound the thread unwinds from the front of the thread, use the small spool cap, and leave a spool.

- Page 46 UPPER THREADING Guide the thread down, up, then down Pass the thread through the thread guide through the groove, as shown in the disks (marked “7”). Make sure that the illustration. thread passes through the groove in the thread guide. a Groove in thread guide Memo Pull the thread up through the thread cutter...

-

Page 47: Using The Twin Needle Mode

UPPER THREADING Press the “Automatic Threading” button to have the machine automatically thread the Note • Some needles cannot be threaded with the needle. needle threader. In this case, instead of using the needle threader after passing the thread through the needle bar thread guide (marked “6”), manually pass the thread through the eye of the needle from the front to the back. - Page 48 UPPER THREADING Press and install the twin needle Place the additional spool of thread on the (“CHANGING THE NEEDLE” on page B-51). supplemental spool pin, so that the thread unwinds from the front. Push the spool cap onto the spool pin as far as possible to secure the thread spool.

-

Page 49: Using Threads That Unwind Quickly

UPPER THREADING Continue threading however do not pass Start sewing. the thread in the needle bar thread guide Sample of Twin Needle Sewing “6” on the needle bar. Thread the needle on the right side. a Needle bar thread guide Memo Press •... -

Page 50: Using The Vertical Spool Pin

UPPER THREADING ■ Using the Vertical Spool Pin Use the vertical spool pin when using an irregularly shaped thread spool, and when sewing with metallic thread. Insert the vertical spool pin onto the bobbin winder shaft. a Bobbin winder shaft b Vertical spool pin c Spool felt d Thread spool... -

Page 51: Changing The Presser Foot

CHANGING THE PRESSER FOOT CHANGING THE PRESSER FOOT CAUTION • Always press on the screen before changing the presser foot. If is not pressed and the “Start/Stop” button or another button is pressed, the machine will start and may cause injury. •... -

Page 52: Attaching The Free Motion Echo Quilting Foot "E

CHANGING THE PRESSER FOOT ■ Attaching the Free Motion Echo Attach the free motion echo quilting foot “E” on the left side of the adapter with the Quilting Foot “E” holes in the quilting foot and adapter aligned. Follow the steps in “Removing the Presser Foot”... -

Page 53: Changing The Needle

CHANGING THE NEEDLE CHANGING THE NEEDLE Use the screwdriver to turn the screw toward the front of the machine and loosen CAUTION the screw. Remove the needle. • Always press on the screen before changing the needle. If is not pressed and the Start/Stop button or another operation button is pressed accidentally, the machine will start and injury may result. -

Page 54: About The Needle And Fabric

ABOUT THE NEEDLE AND FABRIC ABOUT THE NEEDLE AND FABRIC About the Needle The sewing machine needle is probably the most important part of the sewing machine. Choosing the proper needle for your sewing project will result in a beautiful finish and fewer problems. Below are some things to keep in mind about needles. -

Page 55: Using Functions By Connecting The Accessory To The Machine

USING FUNCTIONS BY CONNECTING THE ACCESSORY TO THE MACHINE USING FUNCTIONS BY CONNECTING THE ACCESSORY TO THE MACHINE Using USB Media Connecting the Machine to the Computer Using the included USB cable, the sewing machine can be connected to your computer. a USB port for mouse / media b USB media Memo... -

Page 56: Using A Usb Mouse

USING FUNCTIONS BY CONNECTING THE ACCESSORY TO THE MACHINE ■ Changing Pages Using a USB Mouse Rotate the mouse wheel to switch through the tabs of the pattern selection screens. The USB mouse, connected to the sewing machine, can be used to perform a variety of Memo operations in the screens. -

Page 57: Attaching The Dual Feed Foot

USING FUNCTIONS BY CONNECTING THE ACCESSORY TO THE MACHINE ■ Attaching the Dual Feed Foot Use the included screwdriver to loosen the screw of the presser foot holder, then Press the “Needle Position” button to raise remove the presser foot holder. the needle. -

Page 58: When The Snap-On Foot Of The Dual Feed Foot Is Detached

USING FUNCTIONS BY CONNECTING THE ACCESSORY TO THE MACHINE ■ Using the Dual Feed Position Lever Plug the connector of the dual feed foot into the jack on the back of your machine. When the feed position lever is up, the black roller belt on the dual feed is not engaged. - Page 59 USING FUNCTIONS BY CONNECTING THE ACCESSORY TO THE MACHINE to increase or decrease the feeding of the top fabric. Select “00” for sewing in most cases. If the feed amount for the top fabric is too little, causing the fabric to be longer than the bottom fabric, press to increase the feed amount for the top fabric.

-

Page 60: Chapter2 Sensor Functions

BBasic operations Chapter Sensor Functions CONVENIENT SEWING FEATURES BY USING THE SENSOR PEN............59 CONNECTING THE SENSOR PEN ......59 Using the Sensor Pen Holder ............60 USING THE SENSOR PEN........61 Using the Sensor Pen ..............61 Important Information about Sensor Pen........61 Calibrating the Sensor Pen............62 USING SENSOR FUNCTIONS WITH SEWING STITCH.. -

Page 61: Convenient Sewing Features By Using The Sensor Pen

CONVENIENT SEWING FEATURES BY USING THE SENSOR PEN CONVENIENT SEWING FEATURES BY USING THE SENSOR PEN By using the sensor pen, you have the option of four separate functions • Setting the guideline as a reference for your sewing position. •... -

Page 62: Using The Sensor Pen Holder

CONNECTING THE SENSOR PEN Set the sensor pen in the sensor pen holder Using the Sensor Pen Holder with the pen tip pointing downward, and then connect the sensor pen to the machine. When connecting the sensor pen to the machine, attach the sensor pen holder to keep the sensor pen with the machine. -

Page 63: Using The Sensor Pen

USING THE SENSOR PEN USING THE SENSOR PEN Using the Sensor Pen Important Information about Sensor Pen Hold the sensor pen, and then touch the point to be specified. When the tip of the sensor pen is The sensor pen emits the signal to the machine, pushed in, the position information is sent to the and then the sensor pen receiver receives the machine. -

Page 64: Calibrating The Sensor Pen

USING THE SENSOR PEN Touch the first point of green dot marking Calibrating the Sensor Pen using the sensor pen. Before using the sensor pen for the first time be sure to calibrate it to the screen. Doing so allows the machine to learn the position you usually hold a pen. - Page 65 USING THE SENSOR PEN Press to finish the calibration. To repeat the calibration touch the first point again using the sensor pen, and continue with step Press to return to the original screen without finishing the calibration. Press to reset the calibration. Basic operations B-63...

-

Page 66: Using Sensor Functions With Sewing Stitch

USING SENSOR FUNCTIONS WITH SEWING STITCH USING SENSOR FUNCTIONS WITH SEWING STITCH Before using the sensor functions, carefully read “Utility Stitches” chapter to familiarize yourself with the machine operations. The sensor functions are performed using the sensor pen. Sensor Function Area Memo •... - Page 67 USING SENSOR FUNCTIONS WITH SEWING STITCH Press Memo • The position can be precisely adjusted by touching the adjustment areas with the sensor pen. • When using the sensor pen to specify the guideline marker position, it may not be possible to exactly specify the desired location.

-

Page 68: Specifying The Needle Drop Position With The Sensor Pen

USING SENSOR FUNCTIONS WITH SEWING STITCH With the sensor pen, touch the location to Specifying the Needle Drop be specified as the needle drop position. Position With the Sensor Pen → The guideline marker moves to the touched position and flashes. →... -

Page 69: Using The Sensor Pen To Specify The Stitching Width And Stitch Position

USING SENSOR FUNCTIONS WITH SEWING STITCH Press to apply the reference position Press setting. The setting can also be applied by long touching an adjustment area with the sensor pen. → The needle moves to the specified position to start sewing. - Page 70 USING SENSOR FUNCTIONS WITH SEWING STITCH Press to apply the second point of the Note stitching width. • The following error message appears if the The setting can also be applied by long touching an area outside of the sensor pen touch range adjustment area with the sensor pen.

-

Page 71: Using The Sensor Pen To Specify The Sewing End Point

USING SENSOR FUNCTIONS WITH SEWING STITCH With the sensor pen, touch the location to Using the Sensor Pen to Specify be specified as the sewing end point. the Sewing End Point → The distance from the current needle position to the touched location appears. - Page 72 USING SENSOR FUNCTIONS WITH SEWING STITCH Decorative Stitch End Setting Key Note The end of stitching is not adjusted. • The displayed distance is not the length of a When the end point is reached, sewing straight line connecting the current needle stops immediately, even if the stitch position and the location touched with the pattern is not complete.

- Page 73 Sewing This section describes procedures for using the various utility stitches as well as other functions. It provides details on basic sewing in addition to the more expressive features of the machine, from sewing tubular pieces and buttonholes to sewing the character and decorative stitch patterns. Page number starts with “S”...

-

Page 74: S Sewing

Sewing Chapter Sewing Basics SEWING..............3 Sewing a Stitch ................3 ■ Using the Foot Controller ............4 Sewing Reinforcement Stitches ..........5 Automatic Reinforcement Stitching ...........5 Sewing Curves ................7 Changing Sewing Direction ............7 ■ Sewing a Seam Allowance of 0.5 cm or Less ......7 Sewing Heavyweight Fabrics ............7 ■... -

Page 75: Sewing

SEWING SEWING CAUTION • To avoid injury, pay special attention to the needle while the machine is in operation. Keep your hands away from moving parts while the machine is in operation. • Do not stretch or pull the fabric during sewing. Doing so may lead to injury. •... -

Page 76: Using The Foot Controller

SEWING Press the “Start/Stop” button to start Note sewing. • When cutting thread thicker than #30, nylon Guide the fabric lightly by hand. monofilament thread, or other decorative threads, use the thread cutter on the side of the machine. When the needle has stopped moving, raise Memo the presser foot and remove the fabric. -

Page 77: Sewing Reinforcement Stitches

SEWING Insert the foot controller plug into its jack If the automatic reinforcement stitch is selected on the screen, reverse stitches (or reinforcement on the machine. stitches) will be sewn automatically at the beginning of sewing when the “Start/Stop” button is pressed. - Page 78 SEWING Press the “Reverse Stitch” button or Press to set the automatic “Reinforcement Stitch” button. reinforcement stitching function. a Reverse stitches (or reinforcement stitches) → The machine will sew reverse stitches (or reinforcement stitches) and stop. Memo • To turn off the automatic reinforcement stitching function, press again, so it appears as...

-

Page 79: Sewing Curves

SEWING ■ Sewing a Seam Allowance of 0.5 cm Stitch Stitch name (Example) or Less Applications Baste the corner before sewing, and then, after changing the sewing direction at the corner, pull the Character/Decorative stitch basting thread toward the back while sewing. “Reinforcement Stitch”... -

Page 80: Sewing Hook-And-Loop Fastener

SEWING ■ If the Fabric does not Fit under the Release the black button. Presser Foot If the presser foot is in the up position, and you are sewing heavyweight or multiple layers of fabric which do not fit easily under the presser foot, use the presser foot lever to raise the presser foot to its highest position. -

Page 81: Sewing Lightweight Fabrics

SEWING Sewing Lightweight Fabrics Place thin paper or tear away embroidery stabilizer under thin fabrics to make sewing easier. Gently tear off the paper or the stabilizer after sewing. a Thin paper Sewing Stretch Fabrics First, baste together the pieces of fabric, and then sew without stretching the fabric. -

Page 82: Stitch Settings

STITCH SETTINGS STITCH SETTINGS When you select a stitch, your machine automatically selects the appropriate stitch width, stitch length, “L/R SHIFT”, and upper thread tension. However, if needed, you can change any of the individual settings. Note • Settings for some stitches cannot be changed (refer to the “STITCH SETTING CHART” on page S-67). •... -

Page 83: Setting The "L/R Shift

STITCH SETTINGS Example: Setting the “L/R SHIFT” Press to shorten the stitch length. Follow the steps below when you want to change the placement of the zigzag stitch pattern by moving it left and right. Example: Press to shift the pattern to the left. →... -

Page 84: Setting The Thread Tension

STITCH SETTINGS Press , to loosen the upper thread. Setting the Thread Tension Memo You may need to change the thread tension, • When you finish sewing, remove the bobbin depending on the fabric and thread being used. cover and then make sure that the thread is Follow the steps below to make any necessary shown as below. -

Page 85: Useful Functions

USEFUL FUNCTIONS USEFUL FUNCTIONS Set the fabric in the start position and start Automatic Thread Cutting sewing. After selecting a stitch pattern, turn on the automatic thread cutting function before sewing, and the machine will automatically sew reinforcement stitches (or reverse stitches, depending on the stitch pattern) at the beginning and end of sewing, and trim the threads at the end of sewing. -

Page 86: Adjusting The Needle Drop Position With The Guideline Marker (For Models Equipped With The Guideline Marker)

USEFUL FUNCTIONS Press again to stop using the guideline Adjusting the Needle Drop marker. Position with the Guideline Marker (For models equipped ■ Adjusting the Guideline Marker with the guideline marker) Position If the guideline marker indicates the position The red guideline marker indicates the sewing incorrectly in the center needle position, adjust the position on the fabric. -

Page 87: Using The Knee Lifter

USEFUL FUNCTIONS Use your knee to move the knee lifter bar to to adjust the brightness of the right in order to raise the presser foot. the guideline marker. Release the knee lifter to lower the presser → Set the brightness of the guideline marker from “1” foot. - Page 88 USEFUL FUNCTIONS Select a stitch. Memo • When the pivot setting is selected, the Press to select the pivot setting. height of the presser foot when sewing is stopped can be changed according to the type of fabric being sewn. Press display “Pivoting Height”...

-

Page 89: Automatic Fabric Sensor System (Automatic Presser Foot Pressure)

USEFUL FUNCTIONS Press the “Start/Stop” button to stop the Automatic Fabric Sensor System machine at the point where the sewing direction changes. (Automatic Presser Foot Pressure) The thickness of the fabric is automatically detected and the presser foot pressure is automatically adjusted with an internal sensor while sewing, to insure that your fabric is fed smoothly. -

Page 90: Needle Position - Stitch Placement

USEFUL FUNCTIONS Needle Position – Stitch Locking the Screen Placement If the screen is locked before starting to sew, the various settings such as the stitch width and stitch When the “Needle Position – Stitch Placement” is length are locked and cannot be changed. This on, the needle will be partially lowered for precise prevents screen settings from accidentally being stitch placement and then press the “Needle... - Page 91 USEFUL FUNCTIONS Sewing S-19...

-

Page 92: Chapter2 Utility Stitches

Sewing Chapter Utility Stitches SELECTING UTILITY STITCHES ....... 21 Bar Tacks ................. 59 ■ Bar Tacks on Thick Fabrics ............61 Selecting a Stitch ..............21 Button Sewing ................. 61 ■ Using the Mirror Image Key ............ 21 ■ Attaching 4 Hole Buttons............62 ■... -

Page 93: Selecting Utility Stitches

SELECTING UTILITY STITCHES SELECTING UTILITY STITCHES ■ Using the Mirror Image Key Selecting a Stitch Depending on the type of utility stitch you select, you may be able to sew a horizontal mirror image of There are 5 categories of Utility Stitches. the stitch. -

Page 94: Saving Your Stitch Settings

SELECTING UTILITY STITCHES ■ Using the Image Key Saving Your Stitch Settings You can display an image of the selected stitch. You can check and change the colors of the image of the The settings for the zigzag stitch width, stitch screen. -

Page 95: Retrieving Saved Settings

SELECTING UTILITY STITCHES ■ Retrieving Saved Settings Select a stitch. Memo • When a stitch is selected, the last settings retrieved are displayed. The last settings retrieved are retained even if the machine was turned off or a different stitch was selected. -

Page 96: Sewing The Stitches

SEWING THE STITCHES SEWING THE STITCHES Straight Stitches Memo • Refer to “Sewing Reinforcement Stitches” on page S-5 for the detailed See page S-67 for the detailed information of information of reverse stitches and stitches. reinforcement stitches. Stitch Stitch name Presser foot Select a stitch. -

Page 97: Changing The Needle Position (Left Or Middle Needle Position Stitches Only)

SEWING THE STITCHES ■ Changing the Needle Position (Left Press the “Start/Stop” button to sew forward. or Middle Needle Position Stitches Only) When you select left or middle needle position stitches, you can use in the stitch width display to change the position of the needle. Match the distance from the right edge of the presser foot to the needle with the stitch width, then align the edge of the presser foot with the edge of the... -

Page 98: Aligning The Fabric With A Mark On The Needle Plate Or Bobbin Cover (With Mark)

SEWING THE STITCHES ■ Aligning the Fabric with a Mark on ■ Using the Straight Stitch Needle the Needle Plate or Bobbin Cover Plate and the Straight Stitch Foot (with Mark) The straight stitch needle plate and the straight stitch foot can only be used for straight stitches (middle While sewing, align the edge of the fabric with the needle position stitches). - Page 99 SEWING THE STITCHES Grasp the bobbin case, and then pull it out. Insert the bobbin case in its original position, and then attach the needle plate cover. After reinstalling the needle plate cover, select any of the straight stitches. Memo •...

-

Page 100: Dart Seam

SEWING THE STITCHES ■ Basting Dart Seam Select and attach presser foot “J”. Select and attach presser foot “J”. Press the “Reverse Stitch” button to sew reinforcement stitches, then continue Sew a reverse stitch at the beginning of the sewing. dart and then sew from the wide end to the other end without stretching the fabric. -

Page 101: Gathering

SEWING THE STITCHES Iron the dart to one side so that it is flat. Sew two rows of straight stitches parallel to the seam line, then trim excess thread leaving 50 mm (approx. 1-15/16 inches). a Seam line Gathering b 10 mm to 15 mm (approx. 3/8 inch to 9/16 inch) c About 50 mm (approx. -

Page 102: Pintuck

SEWING THE STITCHES reinforcement stitch and trim the thread Finished flat fell seam automatically at the end of sewing. a Surface Pintuck a About 12 mm (approx. 1/2 inch) b Wrong side Mark along the folds on the wrong side of Spread the fabric out along the finish line. -

Page 103: Zigzag Stitches

SEWING THE STITCHES Sew a straight stitch along the fold. Select a stitch. When the automatic thread cutting and automatic reinforcement stitching are preset, reinforcement stitches will be sewn automatically at the beginning of sewing. Press the “Reverse Stitch” button to sew a reinforcement stitch and trim the thread automatically at the end of sewing. -

Page 104: Patchwork (For Crazy Quilt)

SEWING THE STITCHES ■ Patchwork (for Crazy Quilt) Snap the cord guide bobbin cover into place, making sure that the gimp thread can Turn back the desired width of fabric and position it be fed freely. over the lower fabric, then sew so that the stitch bridges both pieces of fabric. -

Page 105: Elastic Zigzag Stitches

SEWING THE STITCHES ■ Overcasting Elastic Zigzag Stitches Use this stitch to sew overcasting on the edge of stretch fabrics. Sew the overcasting along the edge Use elastic zigzag stitches for tape attaching, of the fabric while positioning the right-hand side overcasting, darning, or a wide variety of other needle drop point just outside the edge of the fabric. -

Page 106: Overcasting Using Presser Foot "J

SEWING THE STITCHES Select a stitch and attach presser foot “G”. CAUTION • After the stitch width is adjusted, rotate the handwheel toward you (counterclockwise). Check that the needle does not touch the presser foot. If the needle hits the presser foot, the needle may break and cause injury. -

Page 107: Quilting

SEWING THE STITCHES Sew with the needle dropping slightly off Presser foot the edge of the fabric. Stitch Stitch name Stem stitch Quilting appliqué zigzag stitch Zigzag stitch (Right) a Needle drop position Zigzag stitch (Left) Note • Use the “L/R SHIFT” setting for fine tuning 2 steps elastic zigzag the placement of the stitch. -

Page 108: Piecing

SEWING THE STITCHES Presser foot Note Stitch Stitch name • The width range of stitch setting is only available in the Quilting stitch “Q” quilting category. Rick-rack stitch ■ Piecing Sewing two pieces of fabric together is called Decorative stitch piecing. -

Page 109: Piecing Using The 1/4" Quilting Foot With Guide (Optional With Some Models)

SEWING THE STITCHES Creating an accurate seam allowance Use the mark on the foot to begin, end, or pivot 1/4 Memo inch from edge of fabric. • Using a straight stitch (middle needle position) makes it easier to sew smoothly (see page S-24). -

Page 110: Appliqué

SEWING THE STITCHES ■ Appliqué Use the quilting appliqué stitch to attach the appliqué. Sew around the edge while Trace the pattern onto the appliqué fabric dropping the needle as close to the edge as and then cut around it, leaving a 3 mm to possible. -

Page 111: Quilting With Satin Stitches

SEWING THE STITCHES You can use the appliqué technique to attach Set the “Width Control” to “ON”. appliqué designs like the three pictured below. a Dresden plate b Stained glass Memo c Sunbonnet sue • You can use the speed control slide to ■... -

Page 112: Free Motion Quilting

SEWING THE STITCHES ■ Free Motion Quilting Memo With free motion quilting, the feed dogs can be • When starting to sew, the internal sensor detects the thickness of the fabric, and the lowered by pressing , so that the fabric can be quilting foot is raised to the height specified moved freely in any direction. - Page 113 SEWING THE STITCHES Attach free motion open toe quilting foot Press to cancel the free motion sewing “O” by positioning the pin of the quilting mode. foot above the needle clamp screw and → Rotate the handwheel toward you aligning the lower-left of the quilting foot (counterclockwise) to raise the feed dogs.

- Page 114 SEWING THE STITCHES Attach the straight stitch needle plate (see → The key appears as , the quilting foot is raised to page S-26). the necessary height, and then the feed dogs are lowered for free motion sewing. a Round hole Memo •...

-

Page 115: Echo Quilting Using The Free Motion Echo Quilting Foot "E" (Optional With Some Models)

SEWING THE STITCHES Hold the quilting foot in place with your After sewing, make sure to remove the right hand, and tighten the presser foot straight stitch needle plate and presser foot holder screw using the screwdriver with “C”, and reinstall the regular needle plate your left hand. - Page 116 SEWING THE STITCHES → The key appears as , the quilting foot is raised to CAUTION the necessary height, then the feed dogs are lowered for free motion sewing. • With free motion quilting, control the feeding speed of the fabric to match the sewing speed. Attach the adapter (“Attaching the Presser If the fabric is moved faster than the sewing Foot with the Included Adapter”...

-

Page 117: Blind Hem Stitches

SEWING THE STITCHES Using the measurement on the quilting foot Blind Hem Stitches as a guide, sew around the motif. Secure the bottoms of skirts and pants with a blind hem. Two stitches are available for blind hem stitching. Stitch Stitch name Presser foot Blind hem stitch... - Page 118 SEWING THE STITCHES Use a chalk to mark on the fabric about 5 Select mm (3/16 inch) from the edge of the fabric, and then baste it. a Wrong side of fabric b Right side of fabric c Edge of fabric d Desired edge of hem e 5 mm (3/16 inch) f Basting...

-

Page 119: If The Needle Catches Too Much Of The Hem Fold

SEWING THE STITCHES ■ If the Needle Catches Too Much of Adjust the stitch width until the needle slightly catches the fold of the hem. the Hem Fold The needle is too far to the left. Press to decrease the stitch width so that the needle slightly catches the fold of the hem. -

Page 120: Appliqué

SEWING THE STITCHES <Normal fabric> Attach presser foot “J”. Check that the needle drops slightly off the edge of the appliqué, then start sewing. a Wrong side of fabric b Right side of fabric Sew with the fold of the hem against the presser foot guide. -

Page 121: Shelltuck Stitches

SEWING THE STITCHES ■ Appliqué Corners To make rows of shell tuck stitches, fold the fabric in half along the bias. Stop the machine with the needle in the right position of the outside (or inside) corner of the appliqué. Raise the presser foot and pivot the fabric to align the fabric edge. -

Page 122: Scallop Stitches

SEWING THE STITCHES Unfold the fabric, and iron the tucks to one Trim along the seam, making sure not to cut side. the stitches. Memo Memo • To make shell tucks at the edge of a collar • Use a seam sealant to secure the edges of or neckline, follow the pattern’s instructions the scallop stitches. -

Page 123: Smocking Stitches

SEWING THE STITCHES Select a stitch for top stitching. Pull the bobbin threads to obtain the desired amount of gather, and then smooth the gathers by ironing them. Place the fabric right side up in the machine, and center the presser foot over the seam when sewing. -

Page 124: Fagoting

SEWING THE STITCHES Fagoting Tape or Elastic Attaching When there is a space between two fabrics with Select a straight stitch and attach presser thread sewn over the space to join the fabrics foot “J”. together, it is called fagoting. Use this stitch when sewing blouses or children’s clothes. -

Page 125: Heirloom

SEWING THE STITCHES Select Heirloom ■ Hemstitching (1) Memo Use for sewing tablecloths, decorative hems, and • For details on each stitch, refer to the decorative stitching on shirt fronts. “STITCH SETTING CHART” on page S-67. Sew over the tape (or elastic). Memo •... -

Page 126: Hemstitching (2) (Drawn Work (1))

SEWING THE STITCHES Start sewing. Press to create a mirror image of the stitch. Example: Illustration of finished product Match beginning needle drop points on the opposite edge of the open area to keep the stitching symmetrical. ■ Hemstitching (2) (Drawn Work (1)) Pull out several threads from one area on a piece of fabric to open the area. -

Page 127: One-Step Buttonholes

SEWING THE STITCHES Sew the decorative stitch in the center of Stitch Stitch name Presser foot the five threads created above. Bound buttonhole Keyhole buttonhole Tapered keyhole buttonhole Keyhole buttonhole Memo One-step buttonholes are sewn from the front of • A wing needle can be used for Hemstitching the presser foot to the back, as shown below. - Page 128 SEWING THE STITCHES Select a buttonhole stitch, and attach buttonhole foot “A”. Note • Pass the thread underneath the presser Mark the position and length of the foot. buttonhole on the fabric. • Slide the outside frame of the buttonhole foot backward as far as possible as shown in the illustration, making sure that there is no gap behind the part of the foot marked...

-

Page 129: Sewing Stretch Fabrics

SEWING THE STITCHES ■ Sewing Stretch Fabrics Memo • If automatic thread cutting is turned on When sewing on stretch fabric with before you start sewing, both threads are automatically cut after the reinforcement sew the buttonhole stitches over a gimp thread. stitches are sewn. -

Page 130: Darning

SEWING THE STITCHES ■ Odd Shaped Buttons/Buttons that do Darning Not Fit into the Button Holder Plate Use the markings on the presser foot scale to set the Use darning stitches for mending and other size of the buttonhole. One mark on the presser foot applications. -

Page 131: Bar Tacks

SEWING THE STITCHES Check that the needle drops at the desired Gently hold the end of the upper thread, position and lower the presser foot, making and then press the “Start/Stop” button to sure the upper thread passes underneath start the machine. the buttonhole foot. - Page 132 SEWING THE STITCHES Lower the buttonhole lever so that it is Memo positioned behind the metal bracket on the • Bar tacks can be between 5 mm (approx. buttonhole foot. 3/16 inch) and 28 mm (approx. 1-1/16 inches). Bar tacks are usually between 5 mm (approx.

-

Page 133: Button Sewing

SEWING THE STITCHES ■ Bar Tacks on Thick Fabrics Attach button sewing foot “M”, slide the button along the metal plate and into the Place a piece of folded fabric or cardboard beside presser foot, and lower the presser foot. the fabric being sewn to level the buttonhole foot and allow for easier and even feeding. -

Page 134: Eyelet

SEWING THE STITCHES ■ Attaching 4 Hole Buttons Eyelet Sew the two holes closest to you. Then raise the presser foot and move the fabric so that the needle Use this stitch for making belt holes and other goes into the next two holes, and sew them in the similar applications. -

Page 135: Multi-Directional Sewing (Straight Stitch And Zigzag Stitch)

SEWING THE STITCHES Use the eyelet punch to make a hole in the center of the stitching. Memo • For details on each stitch, refer to the “STITCH SETTING CHART” on page S-67. Set the needle in the fabric at the sewing start point, and sew seam “1”... -

Page 136: Zipper Insertion

SEWING THE STITCHES Press the seam allowance open and attach Select and sew seam “4” as shown. the zipper with a basting stitch in the middle of each side of the zipper tape. → The seam will be connected to the starting point of a Basting stitches seam 1. -

Page 137: Inserting A Side Zipper

SEWING THE STITCHES Topstitch 7 mm to 10 mm (approx. 1/4 inch Press the seam allowance open and align to 3/8 inch) from the seamed edge of the the folded hem along the teeth of the fabric, then remove the basting. zipper, while maintaining 3 mm (approx. - Page 138 SEWING THE STITCHES Starting from the end of the zipper opening, Remove the presser foot, and reattach it so sew to a point about 50 mm (approx. that the left side of the pin is attached to the 2 inches) from the edge of the fabric, then presser foot holder.

-

Page 139: Stitch Setting Chart

STITCH SETTING CHART STITCH SETTING CHART The following chart shows information for each utility stitch concerning applications, stitch lengths, stitch widths, and whether or not the twin needle mode can be used. Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch... - Page 140 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Overcasting Reinforcing of heavyweight 2.5 - 5.0 0.4 - 5.0 stitch fabric (3/16) (3/32 - 3/16) (3/32) (1/64 - 3/16) Overcasting Reinforcing of medium,...

- Page 141 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Quilting Quilting stitch for invisible 0.0 - 7.0 0.4 - 5.0 appliqué stitch appliqué or attaching binding (1/16) (0 - 1/4) (1/16)

- Page 142 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Serpentine Decorative stitching and 0.0 - 7.0 0.2 - 5.0 stitch attaching elastic (3/16) (0 - 1/4) (1/16) (1/64 - 3/16) ( J )

- Page 143 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Hemstitching Heirloom, decorative hems 0.0 - 7.0 0.4 - 5.0 (15/64) (0 - 1/4) (3/16) (1/64 - 3/16) ( J ) Hemstitching Heirloom, decorative hems...

- Page 144 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Keyhole Buttonholes in heavyweight or 3.0 - 7.0 0.3 - 1.0 buttonhole thick fabrics for larger flat (1/4) (1/8 - 1/4) (1/32)

- Page 145 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Forward For attaching appliqué on (Zigzag) tubular pieces of fabric and — — — — mitering corners Reverse For attaching appliqué...

- Page 146 STITCH SETTING CHART Stitch width Stitch length Presser foot [mm (inch)] [mm (inch)] Twin Stitch Stitch name Applications needle Auto. Manual Auto. Manual Tape attaching Attaching tape to seam in 5.50 0.00 - 7.00 0.2 - 5.0 stretch fabric (7/32) (0 - 1/4) (1/16) (1/64 - 3/16)

- Page 147 STITCH SETTING CHART Sewing S-75...

-

Page 148: Chapter3 Character/Decorative Stitches

Sewing Chapter Character/Decorative Stitches SELECTING STITCH PATTERNS ....... 77 Selecting Decorative Stitch Patterns/7mm Decorative Stitch Patterns/Satin Stitch Patterns/7mm Satin Stitch Patterns/Cross Stitch/Utility Decorative Stitch Patterns ...78 Characters ................78 ■ Deleting Characters ..............79 ■ Adjusting the Character Spacing ..........80 SEWING STITCH PATTERNS ........ -

Page 149: Selecting Stitch Patterns

SELECTING STITCH PATTERNS SELECTING STITCH PATTERNS Press to display the screen below. There are 7 categories of Character/Decorative stitch patterns. a Decorative stitch patterns b 7mm decorative stitch patterns. You can set stitch length and width. c Satin stitch patterns d 7mm satin stitch patterns. -

Page 150: Selecting Decorative Stitch Patterns/7Mm Decorative Stitch Patterns/Satin Stitch Patterns/7Mm Satin Stitch Patterns/Cross Stitch/Utility Decorative Stitch Patterns

SELECTING STITCH PATTERNS Selecting Decorative Stitch Characters Patterns/7mm Decorative Stitch Example: Entering “Blue Sky”. Patterns/Satin Stitch Patterns/7mm Satin Stitch Press Patterns/Cross Stitch/Utility Decorative Stitch Patterns Select the category of the pattern you want to sew. Press the key of the stitch pattern you want to sew. -

Page 151: Deleting Characters

SELECTING STITCH PATTERNS Press and then enter “B”. Press and then enter “ky”. If you want to continue entering characters in a Press and then enter “lue”. different font, press , and then repeat from step ■ Deleting Characters Press to delete the last character. -

Page 152: Adjusting The Character Spacing

SELECTING STITCH PATTERNS ■ Adjusting the Character Spacing Press to adjust character spacing. The space between the characters can be adjusted. Press Press to display on the screen. Press to increase the character spacing and press to decrease the character spacing. Example: →... -

Page 153: Sewing Stitch Patterns

SEWING STITCH PATTERNS SEWING STITCH PATTERNS Sewing Attractive Finishes To achieve attractive results when sewing character/decorative stitches, check the table below for the proper fabric/thread/needle combinations. Note • Other factors, such as fabric thickness, stabilizer material, etc., also have an effect on the stitch, so you should always sew a few trial stitches before beginning your project. -

Page 154: Making Adjustments

SEWING STITCH PATTERNS Memo Note • If the fabric is pulled or pushed during • When sewing some patterns, the needle will sewing, the pattern may not turn out temporarily pause in the raised position correctly. Also, depending on the pattern, while the fabric is fed due to the operation there may be movement to the left and right of the needle bar separation mechanism... - Page 155 SEWING STITCH PATTERNS Attach monogramming foot “N” and sew If the pattern is bunched: the pattern. Press in the “Fine Adjust Verti.” display. → The displayed value increases each time the button is pressed and the pattern will lengthen. If the pattern has gaps: Press in the “Fine Adjust Verti.”...

-

Page 156: Editing Stitch Patterns

EDITING STITCH PATTERNS EDITING STITCH PATTERNS ■ Key Functions You can create just the finish you want using the editing functions. Make patterns larger or smaller, make mirror images, etc. Note • Some editing functions cannot be used with certain stitch patterns. Only the functions for the displayed keys are available when a pattern is selected. - Page 157 EDITING STITCH PATTERNS Display Key Name Explanation Page Pivot key Press this key to select the pivot setting. When the pivot setting is S-15 selected, stopping the machine lowers the needle and slightly raises the presser foot automatically. In addition, when sewing is restarted, the presser foot is automatically lowered.

-

Page 158: Changing The Size

EDITING STITCH PATTERNS Changing the Size Creating a Vertical Mirror Image To create a vertical mirror image, select a stitch Select a stitch pattern, then press to change pattern then press the size of the stitch pattern. The stitch pattern will be sewn in the size highlighted on the key. -

Page 159: Changing Thread Density (For Satin Stitch Patterns Only)

EDITING STITCH PATTERNS Memo Returning to the Beginning of the • To finish a complete motif while sewing the Pattern pattern continuously, you can press the key while sewing. The machine will When sewing character/decorative stitches, you automatically stop when the motif is can return to the beginning of the pattern after trial finished. -

Page 160: Checking The Image

EDITING STITCH PATTERNS to view any part of Checking the Image the image that extends out of the viewable display area. You can display an approximate size image of the selected stitch pattern. You can also check and change the colors of the image on the screen. Press →... -

Page 161: Combining Stitch Patterns

COMBINING STITCH PATTERNS COMBINING STITCH PATTERNS You can combine many varieties of stitch patterns, such as character stitches, cross stitches, satin stitches, or stitches you design with “MY CUSTOM STITCH” function (see page S-102 for information about “MY CUSTOM STITCH”). You can also combine stitch patterns of different sizes, mirror image stitch patterns, and others. -

Page 162: Combining Large And Small Stitch Patterns

COMBINING STITCH PATTERNS Select Press → The large size stitch will be selected. Press again, then press to select the small size. Press to sew the pattern continuously. Press → The pattern is displayed in a smaller size. Press to sew continuously. Memo •... -

Page 163: Combining Horizontal Mirror Image Stitch Patterns

COMBINING STITCH PATTERNS Combining Horizontal Mirror Combining Stitch Patterns of Image Stitch Patterns Different Length Example: Example: Press , then press once. Press → The length of the image is set to Press again, then press Select again, then press 3 times. -

Page 164: Making Step Stitch Patterns (For 7Mm Satin Stitch Patterns Only)

COMBINING STITCH PATTERNS Example: Press Press Press → The entered pattern is repeated. Making Step Stitch Patterns (for 7mm Satin Stitch Patterns Only) You can use the keys with 7mm satin → The next stitch pattern will move to the right. stitch patterns to create a step effect. -

Page 165: More Examples

COMBINING STITCH PATTERNS Press → → → Press → → → → → Press → The entered pattern is repeated. ■ More Examples → → → → → → → Press → → → → → Press → → → Sewing S-93... -

Page 166: Using The Memory Function

USING THE MEMORY FUNCTION USING THE MEMORY FUNCTION Stitch Data Precautions Observe the following precautions when using stitch data other than that created and saved in this machine. ■ Types of Stitch Data that can be Used • In the Character/Decorative Stitch memory, “.pmv”, “.pmx” and “.pmu” stitch data files can be used with this machine. -

Page 167: Saving Stitch Patterns In The Machine's Memory

USING THE MEMORY FUNCTION ■ If the Memory is Full Saving Stitch Patterns in the If the following screen appears while you are trying Machine’s Memory to save a pattern on the machine’s memory, the memory is too full to hold the currently selected stitch pattern. -

Page 168: Saving Stitch Patterns To Usb Media

USING THE MEMORY FUNCTION Press Saving Stitch Patterns to USB Media When sending stitch patterns from the machine to USB media, plug the USB media into the machine’s top USB port. Memo • USB media is commercially available, but some USB media may not be usable with this machine. -

Page 169: Saving Stitch Patterns In The Computer

USING THE MEMORY FUNCTION Insert the USB media into the USB port on Saving Stitch Patterns in the the machine. Computer Using the included USB cable, the machine can be connected to your computer, and the stitch patterns can be temporarily retrieved from and saved in the “Removable Disk”... -

Page 170: Retrieving Stitch Patterns From The Machine's Memory

USING THE MEMORY FUNCTION Press Retrieving Stitch Patterns from the Machine’s Memory Press → The pocket selection screen appears. Choose a stitch pattern to retrieve. Press If the entire saved stitch pattern is not displayed, press the thumbnail. Press to return to the original screen without Press to return to the original screen without saving. -

Page 171: Recalling From Usb Media

USING THE MEMORY FUNCTION Press when there is a subfolder to Recalling from USB Media sort two or more stitch patterns to USB media, the stitch pattern in the subfolder is You can recall a specific stitch pattern from either displayed. -

Page 172: Recalling From The Computer

USING THE MEMORY FUNCTION Move/copy the pattern data to “Removable Press Disk”. Press to delete the stitch pattern. The pattern will be deleted from the USB media. → Stitch pattern data in “Removable Disk” is written to the machine. Note •... - Page 173 USING THE MEMORY FUNCTION Press Press to delete the stitch pattern. The pattern will be deleted from the “Removable Disk” folder in your computer. → The selected stitch pattern is recalled and the sewing screen will be displayed. Note • The pattern recalled from the computer is only temporarily written to the machine.

-

Page 174: Chapter4 My Custom Stitch

Sewing Chapter MY CUSTOM STITCH DESIGNING A STITCH .......... 103 ENTERING STITCH DATA ........105 ■ Key Functions................. 105 ■ Moving a Point ..............107 ■ Moving Part or All of the Design ........... 108 ■ Inserting New Points ............. 109 USING STORED CUSTOM STITCHES.... -

Page 175: Designing A Stitch

DESIGNING A STITCH DESIGNING A STITCH Decide the spacing of the stitch. By using the “MY CUSTOM STITCH” function, you can register stitches you have created yourself. You can also sew designs combining “MY By adjusting the spacing of a stitch, you can create CUSTOM STITCH”... - Page 176 DESIGNING A STITCH Examples of Custom Stitches Stitch Stitch Stitch Stitch Stitch Stitch Stitch Stitch Stitch Stitch Stitch Stitch S-104...

-

Page 177: Entering Stitch Data

ENTERING STITCH DATA ENTERING STITCH DATA ■ Key Functions a This area displays the stitch being created. b Displays the number of the present set point over the total number of points in the stitch. c Displays the y-coordinate of over the x-coordinate of Display Key Name... - Page 178 ENTERING STITCH DATA Press to enlarge the image of the stitch being Press created. Press a Currently selected point/Total number of points b Coordinates of Press to add the point indicated by to move to the coordinates To insert coordinates with the touch pen, move the of the first point on the grid sheet.

-

Page 179: Moving A Point

ENTERING STITCH DATA to move to the second point Memo • If you have entered points that are too close together, the fabric may not feed properly. and press Edit the stitch data to leave a larger space between points. •... -

Page 180: Moving Part Or All Of The Design

ENTERING STITCH DATA Press to move the point. → The selected point and all points that were entered after it are selected. ■ Moving Part or All of the Design Press to move the section. Press to move to the first point of the section that you want to move. -

Page 181: Inserting New Points

ENTERING STITCH DATA Press Press → The section will be moved. → A new point is entered and moves to it. ■ Inserting New Points to move the point. Press to move to a place on the design where you want to add a new point. -

Page 182: Using Stored Custom Stitches

USING STORED CUSTOM STITCHES USING STORED CUSTOM STITCHES ■ If the Memory is Full Storing Custom Stitches in Your If the following message appears after List pressed, the stitch pattern cannot be stored because either the machine’s memory is full or the stitch Stitch patterns created using the “MY CUSTOM pattern being stored is larger than the amount of STITCH”... -

Page 183: Retrieving Stored Stitches

USING STORED CUSTOM STITCHES Press Retrieving Stored Stitches To delete the stored stitch pattern, press Press To edit the stored stitch pattern, press → A list of stored stitch patterns is displayed. Select the stitch pattern. Press to return to the previous screen without retrieving. - Page 184 USING STORED CUSTOM STITCHES S-112...

-

Page 185: Appendix

Appendix This section provides important information for operating this machine. Please read this section to find troubleshooting tips and pointers as well as how to keep your machine in the best working order. Page number starts with “A” in this section. The screen display and machine illustration may vary slightly, depending on the countries or regions. -

Page 186: Preparing For Bobbin Work

Appendix Chapter How to Create Bobbin Work ABOUT BOBBIN WORK..........3 PREPARING FOR BOBBIN WORK......3 Required Materials..............3 ■ Bobbin case and bobbin cover ........... 3 ■ Lower thread................4 ■ Upper thread ................4 ■ Needle ..................4 ■ Presser foot ................4 ■... -

Page 187: About Bobbin Work

ABOUT BOBBIN WORK ABOUT BOBBIN WORK Beautiful embroidery work, with a three-dimensional appearance, can be created by winding the bobbin with medium to heavy weight thread or ribbon, which is too thick to be threaded through the machine’s needle. The decorative thread or ribbon will stitch out on the underneath side of fabric while sewing with the fabric wrong side facing up. -

Page 188: Upper Threading

PREPARING FOR BOBBIN WORK ■ Lower thread ■ Presser foot We recommend the following types of threads for Utility stitches or decorative stitches: bobbin work. Monogramming foot “N” No.5 or finer hand embroidery thread or decorative thread Free motion sewing: Free motion quilting foot “C”, Free motion echo quilting foot “E or Free motion open toe quilting foot Flexible woven ribbon... -

Page 189: Preparing The Bobbin Thread

PREPARING FOR BOBBIN WORK Wipe the bobbin case (gray) with a soft lint Preparing the Bobbin Thread free cloth to clean it. Insert the bobbin case so that the mark In order to create bobbin work, the bobbin case on the bobbin case aligns with the ● mark must be replaced with the one for bobbin work. -

Page 190: When Tension Is Applied To The Bobbin Thread

PREPARING FOR BOBBIN WORK ■ When tension is applied to the Wind a decorative thread around the bobbin by hand. After winding the bobbin bobbin thread so it is filled as shown below (about 80%), Insert bobbin into bobbin case so the thread cut the thread. -

Page 191: When Tension Is Not Applied To The Bobbin Thread

PREPARING FOR BOBBIN WORK ■ When tension is not applied to the Gently pull the upper thread to bring the bobbin thread up through the needle plate. bobbin thread If the bobbin thread in the trial stitching is too tight and adjusting the bobbin case tension does not help, do not pass the thread through the tension spring. - Page 192 PREPARING FOR BOBBIN WORK Install the needle plate cover and bobbin cover with tabs. For details on installing the needle plate cover, refer to “Cleaning the Race” on page A-15. a Bobbin cover b Bobbin cover with tabs CAUTION • When creating bobbin work, use the bobbin cover with tabs, otherwise the thread may become tangled or the needle may break.

-

Page 193: Creating Bobbin Work

CREATING BOBBIN WORK CREATING BOBBIN WORK Increase the upper thread tension. Upper Positioning the Fabric and Sewing thread tension setting between 6 and 8 is recommended for bobbin work. For details on adjusting the upper thread tension, Note refer to “Setting the Thread Tension” of •... - Page 194 CREATING BOBBIN WORK Use the presser foot lever to raise the presser foot. Note • If the bobbin thread does not come up, hold With the wrong side facing up, place the the upper thread as shown below to pull up the bobbin thread.

-

Page 195: Bobbin Work Free Motion Sewing

CREATING BOBBIN WORK When you have reached the end of the Working from the wrong side of the fabric, stitching area, stop the machine. tie the bobbin and upper threads together by hand. Cut away excess threads with scissors. Note •... -

Page 196: Adjusting The Thread Tension

ADJUSTING THE THREAD TENSION ADJUSTING THE THREAD TENSION After sewing trial stitches and checking the sewing results, adjust the thread tensions if necessary. After adjusting the tensions, be sure to sew trial stitches again in order to check the sewing results. ■... -

Page 197: Troubleshooting

TROUBLESHOOTING TROUBLESHOOTING Several solutions for minor problems are described below. If the problem persists, contact your dealer or nearest authorized Brother dealer. ■ The thread was accidentally cut Apply slight tension on bobbin thread by holding thread out to the left side of presser automatically and the bobbin thread foot. -

Page 198: Chapter2 Maintenance And Troubleshooting

Appendix Chapter Maintenance and Troubleshooting CARE AND MAINTENANCE ........15 Restrictions on oiling ..............15 Precautions on storing the machine ..........15 Cleaning the LCD Screen ............15 Cleaning the Machine Casing ...........15 Cleaning the Race ..............15 Cleaning the Cutter in the Bobbin Case Area......17 About the Maintenance Message ..........17 ADJUSTING THE SCREEN ........ -

Page 199: Care And Maintenance

CARE AND MAINTENANCE CARE AND MAINTENANCE CAUTION • Be sure to unplug the machine before cleaning it. Otherwise, electric shock or injury may result. Restrictions on oiling Cleaning the Machine Casing In order to prevent damaging this machine, it must If the surface of the machine is dirty, lightly soak a not be oiled by the user. - Page 200 CARE AND MAINTENANCE Use the cleaning brush or a vacuum cleaner Make sure that the indicated points are aligned before installing the bobbin case. to remove any lint and dust from the race and bobbin thread sensor and the CAUTION surrounding area.

-

Page 201: Cleaning The Cutter In The Bobbin Case Area

CARE AND MAINTENANCE Use the screwdriver included with the Cleaning the Cutter in the Bobbin machine to screw and attach the needle plate. Case Area The cutter below the needle plate should be cleaned. If dust or lint accumulate on the cutter, it will be difficult to cut the thread when the “Thread Cutter”... -

Page 202: Adjusting The Screen

ADJUSTING THE SCREEN ADJUSTING THE SCREEN Adjusting the Brightness of the Touch Panel is Malfunctioning Screen Display If the screen does not respond correctly when you touch a key (the machine does not perform the If the screen does not look very clear under certain operation or performs a different operation), follow situation, you can adjust the brightness of the the steps below to make the proper adjustments. -

Page 203: Troubleshooting

TROUBLESHOOTING TROUBLESHOOTING If the machine stops operating correctly, check the following possible problems before requesting service. You can solve most problems by yourself. If you need additional help, the Brother Solutions Center offers the latest FAQs and troubleshooting tips. Visit us at “ http://solutions.brother.com ”. If the problem persists, contact your dealer or the nearest authorized service center. -

Page 204: Tangled Thread On Wrong Side Of Fabric

TROUBLESHOOTING While holding the bobbin in place with Tangled thread on wrong side of your finger, pass the thread through the slit in the needle plate. fabric Hold down the bobbin with your right hand, and then pull the end of the thread around the tab with ■... - Page 205 TROUBLESHOOTING Raise the presser foot using the presser foot While holding the thread in your right lever. hand, pass the thread through the thread guide in the direction indicated. If the presser foot is not raised, the sewing machine cannot be threaded correctly. Guide the thread down, up, then down Raise the needle by turning the handwheel through the groove, as shown in the...

-

Page 206: Incorrect Thread Tension

TROUBLESHOOTING Incorrect thread tension ■ Symptoms • Symptom 1: The lower thread is visible from the upper side of the fabric. • Symptom 2: The upper thread appears as a straight line on the upper side of the fabric. • Symptom 3: The upper thread is visible from the lower side of the fabric. •... -

Page 207: Fabric Is Caught In The Machine And Cannot Be Removed

TROUBLESHOOTING Remove the bobbin case. Fabric is caught in the machine If threads remain in the bobbin case, remove them. and cannot be removed If the fabric is caught in the sewing machine and cannot be removed, the thread may have become tangled under the needle plate. - Page 208 TROUBLESHOOTING Slightly lift up the needle plate, cut any Insert the bobbin case so that the mark on the bobbin case aligns with the ● mark tangled threads, and then remove the needle plate. on the machine. Remove the fabric and threads from the needle plate. If the fabric cannot be removed, even after completing these steps, contact your dealer or nearest authorized service center.

-

Page 209: Checking Machine Operations

TROUBLESHOOTING Insert the tabs on the needle plate cover Slowly turn the handwheel toward you into the needle plate, and then slide the (counterclockwise), and look from all sides cover back on. to check that the needle falls at the center of the hole in the needle plate. -

Page 210: List Of Symptoms

TROUBLESHOOTING List of Symptoms Problem Cause Solution Page The thread is tangled Upper threading is incorrect. Check the steps for threading the machine B-42 on the wrong side of and rethread the machine. the fabric. Using improper needle or thread for the Check the “Fabric/Thread/Needle B-52 selected fabric. - Page 211 TROUBLESHOOTING Problem Cause Solution Page Skipped stitches Needle is turned, bent or the point is dull. Replace the needle. B-51 Using improper needle or thread for the Check the “Fabric/Thread/Needle B-52 selected fabric. Combination” chart. Machine is threaded incorrectly. Check the steps for threading the machine B-42 and rethread it correctly.

- Page 212 TROUBLESHOOTING Problem Cause Solution Page High-pitched sound Dust or lint is caught in the feed dogs. Remove the dust or lint. A-15 while sewing Pieces of thread are caught in the race. Clean the race. A-15 Upper threading is incorrect. Check the steps for threading the machine B-42 and rethread the machine.

-

Page 213: Error Messages

ERROR MESSAGES ERROR MESSAGES If the machine is not properly set and the “Start/Stop” button or the “Reverse Stitch” button is pressed, or if the operation procedure is incorrect, the machine does not start. An alarm sounds and an error message is displayed on the LCD. - Page 214 ERROR MESSAGES Marks Error Messages Cause/Solution OK to delete the setting? This message appears when is pressed to delete the settings for a utility stitch. To delete the selected settings, press Preventive maintenance is recommended. This message is displayed when the machine needs to be maintained.

-

Page 215: Specifications

SPECIFICATIONS Marks Error Messages Cause/Solution This key does not operate when the needle is down. Raise the This message is displayed when a key on the LCD display is needle and press the key again. touched while the needle is in the down position. This pattern cannot be sewn with this mode. -

Page 216: Upgrading Your Machine's Software

UPGRADING YOUR MACHINE’S SOFTWARE UPGRADING YOUR MACHINE’S SOFTWARE You can use USB media or a computer to upgrade software for your sewing machine. When an upgrade program is available on “ http://solutions.brother.com ”, please download the files following the instructions on the website and steps below. Note •... -

Page 217: Upgrade Procedure Using Computer

UPGRADING YOUR MACHINE’S SOFTWARE Upgrade Procedure Using Computer While pressing the “Automatic Threading” button, turn the main power to ON. → The following screen will appear on the LCD. When the message disappears, press Press Plug the USB cable connector into the corresponding USB ports for the computer and for the machine. -

Page 218: Index

INDEX INDEX Dart seam ................. S-28 Dual feed foot ................B-54 Accessories included accessories ............B-13 options ................. B-16 Accessory compartment ............B-13 Eco mode ................. B-28 Adapter ..................B-50 Editing Air vent ..................B-11 character/decorative stitches ..........S-84 Alphabet characters MY CUSTOM STITCH ............ - Page 219 INDEX Reverse/Reinforcement stitches ........... S-5 Main power switch ..........B-11 B-19 B-59 Mirror image key ............S-21 S-86 Multi-directional sewing ............S-63 Satin stitches ..............S-39 S-87 MY CUSTOM STITCH Saving designing ................S-103 character/decorative stitches ..........S-95 entering data ............... S-105 computer ................

- Page 220 INDEX Upgrading ................A-32 Upper threading twin needle mode ..............B-45 using the “Automatic Threading” button ......B-42 using the spool net ............... B-47 USB cable ............B-53 S-97 A-33 USB media recalling ................S-99 saving ................... S-96 usable ................... S-94 USB mouse ..............

- Page 224 http://solutions.brother.com Please visit us at where you can get product support and answers to frequently asked questions (FAQs). English 882-D00 Printed in Taiwan XF3632-001...