Summary of Contents for CAME FROG PLUS

- Page 1 Swing-gate operator FA01648-EN FROG PLUS FROG-PM4 FROG-PM6 INSTALLATION MANUAL EN English...

- Page 3 Machinery Directive (2006/42/EC) and with the reference harmonised technical standards are specified in the general CAME product catalogue or on the website www.came.com. • Make sure the mains power supply is disconnected during all installation procedures. • Check that the temperature ranges given are suitable for the installation site. • Do not install the operator on surfaces that could yield and bend.

- Page 4 • Where operated with a hold-to-run control, install a STOP button to disconnect the main power supply to the operator, to block movement of the guided part. • If not already present, apply a permanent tag that describes how to use the manual release mechanism close to it.

-

Page 5: Intended Use

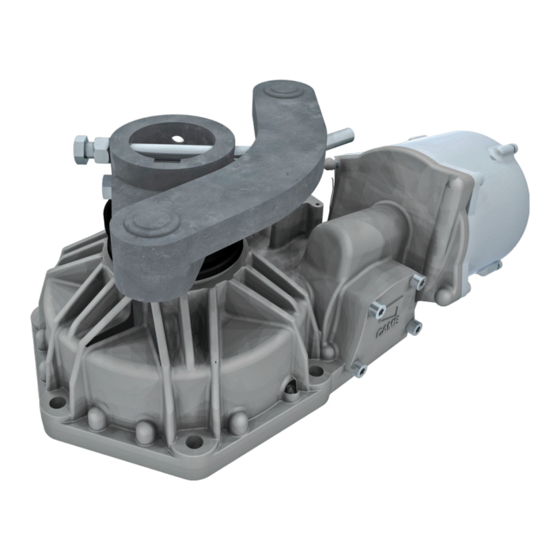

PRODUCT DATA AND INFORMATION This symbol shows which parts to read carefully. This symbol shows which parts describe safety issues. This symbol shows what to tell users. The measurements, unless otherwise stated, are in millimetres. Description FROG-PM4 Underground irreversible 230 V gearmotor with encoder and adjustable leaf-stop during closing, for swing gates with leaves up to 5.5 m in length and 700 kg in weight. FROG-PM6 Underground irreversible 230 V gearmotor with encoder and adjustable leaf-stop during closing, for swing gates with leaves up to 7 m in length and 550 kg in weight. -

Page 6: Usage Limitations

Size Usage limitations For leaves longer than 2.5 m, install an electric lock. MODELS FROG-PM4 FROG-PM6 Gate-leaf length (m) Gate-leaf weight (Kg) 1100 1400 1000 Technical data MODELS FROG-PM4 FROG-PM6 Power supply (V - 50/60 Hz) 230 AC 230 AC Motor power supply (V) 230 AC 230 AC... -

Page 7: Installation

INSTALLATION The following illustrations are examples only. The space available for fitting the operator and accessories varies depending on the area where it is installed. It is up to the installer to find the most suitable solution. The drawings refer to the right-side gearmotor. Preliminary operations The preliminary operations for installation concern the foundation box installation and the release devices fastening. - Page 8 Lubricate the transmission lever. Fit the transmission lever as shown in the drawings. Determining the travel end points with mechanical limit switches Manually open the leaf to the desired point. The leaf maximum opening is 110°. Unscrew the opening limit-switch point adjustment screw until it touches the foundation box. Tighten the nut to lock the screw into position.

-

Page 9: Electrical Connections

ELECTRICAL CONNECTIONS Before working on the control panel, disconnect the mains power supply and remove the batteries, if any. Provide IP67 junction boxes with terminal blocks for connections. Blue cable Power supply cable Brown cable Encoder cable Black cable Yellow/green cable Green cable White cable Check the correct direction of rotation of the gearmotor and, if necessary, invert the connection of the brown and black cables. -

Page 10: Final Operations

FINAL OPERATIONS OUTWARDS OPENING The only operation that is different from the standard installation is described below. Setting up the gearmotor Insert the closing limit-switch point adjustment screw into the gearmotor arm. Gearmotor installed on the left Gearmotor installed on the right... - Page 12 AFFIX THE PRODUCT LABEL FROM THE BOX HERE CAME S.p.A. Via Martiri della Libertà, 15 31030 Dosson di Casier Treviso - Italy Tel. (+39) 0422 4940 Fax (+39) 0422 4941...