Summary of Contents for Labtech LT-4500

- Page 1 Instructions for Use for Absorbance Reader Document Name: LT-4500 IFU Document Revision No.: 1.0...

- Page 2 Bellbrook Ind Estate Uckfield TN22 1QQ United Kingdom Copyright Information The contents of this document are the property of labtech.com and are not to be copied, reproduced, or transferred to another person or persons without prior written permission. Copyright labtech.com All rights reserved.

- Page 3 Warnings, Cautions, and Notes The following types of notices are used throughout this publication to highlight important information or to warn the user of potentially dangerous situations: Note Gives helpful information. CAUTION INDICATES A POSSIBILITY OF INSTRUMENT DAMAGE OR DATA LOSS IF INSTRUCTIONS ARE NOT FOLLOWED.

-

Page 5: Table Of Contents

Table of Contents 1. Safety ....................9 Instrument Safety ..............9 2. General ....................11 Intended Use / Introduction ..........11 User Profile ................12 2.2.1 Professional User - Administrator Level........12 2.2.2 End User or Routine User ............12 3. - Page 6 Instrument Disinfection ............70 7.3.1 Disinfection Solutions ............... 71 7.3.2 Disinfection Procedure ............. 71 7.3.3 Safety Certificate..............73 Preventive Maintenance Plan for LT-4500 ......74 7.4.1 Monthly ..................74 7.4.2 Every 4 Years ................74 Filter Replacement and Installation ........74 7.5.1 Filter Switching Procedure ............

- Page 7 7.6.2 Disposal of Packing Material ........... 78 7.6.3 Disposal of Operating Material ..........79 7.6.4 Disposal of the Instrument ............79 8. Troubleshooting ................81 Introduction ................81 8.1.1 Table of Error Messages and Troubleshooting ......81 8.1.2 Definition of ‘Overflow’ ............. 82 8.1.3 Power Failure ................

-

Page 9: Safety

• Safety data sheets of the reagent manufacturers WARNING DEPENDING ON THE APPLICATIONS, PARTS OF THE LT-4500 MAY COME IN CONTACT WITH BIOHAZARDOUS/INFECTIOUS MATERIAL. MAKE SURE THAT ONLY QUALIFIED PERSONNEL OPERATE THE INSTRUMENT. IN CASE OF SERVICE OR WHEN RELOCATING OR... - Page 10 1. Safety WARNING THE INSTRUMENT COMPLIES WITH THE EMISSION AND IMMUNITY REQUIREMENTS DESCRIBED IN IEC 61326-2-6; HOWEVER, THE ELECTROMAGNETIC ENVIRONMENT SHOULD BE EVALUATED PRIOR TO THE OPERATION OF THE INSTRUMENT. IT IS THE OPERATOR'S RESPONSIBILITY TO ENSURE THAT A COMPATIBLE ELECTROMAGNETIC ENVIRONMENT FOR THE INSTRUMENT IS MAINTAINED, SO THAT THE INSTRUMENT PERFORMS AS INTENDED.

-

Page 11: General

Note If the LT-4500 absorbance reader or the LT-com software is modified in any way, the warranty will no longer be valid and the instrument will lose regulatory conformity. -

Page 12: User Profile

The administrator has extensive skills and is able to instruct the end user or the routine user in assay protocols in connection with a Labtech product within the bounds of the intended use. -

Page 13: Getting Started

3. Getting Started Getting Started Unpacking and Inspection 3.1.1 Inspection of Delivered Packaging The delivered instrument includes: • External power supply • Power cable • USB cable for connection to external computer • Instructions for Use (IFU), printed • USB stick Software (LT-com) Instructions for Use (IFU), PDF files Tools (e.g. -

Page 14: Power Requirements

3. Getting Started Power Requirements The instrument is auto-sensing for the supplied voltage. Therefore, it is not necessary to make any changes to the voltage range. Check the voltage specifications and ensure that the voltage supplied to the instrument is correct according to the following specifications: Voltage: Basic instrument with AC adapter:... -

Page 15: System Requirements

3. Getting Started System Requirements 3.4.1 Hardware requirements The following requirements have to be met for using LT-com: Hardware Minimum Recommended Memory 512 MB 1024 MB Pentium III or Atom Pentium IV Resolution 1024 x 600 1280 x 1024 1 (USB 2.0 or 2 (USB 2.0 or USB ports higher) -

Page 16: Switching On The Instrument

3. Getting Started Switching ON the Instrument The following procedures detail the necessary steps required before switching on the instrument. CAUTION BEFORE THE INSTRUMENT IS INSTALLED AND SWITCHED ON, IT SHOULD BE LEFT TO STAND FOR AT LEAST THREE HOURS, SO THERE IS NO POSSIBILITY OF CONDENSATION CAUSING A SHORT CIRCUIT. -

Page 17: Software

3.6.1 Introduction The instrument control and data analysis software LT-com is delivered with the instrument. This version of LT-com is only compatible with the LT-4500 absorbance reader. LT-com is a universal reader control and data analysis software for analyzing data generated by microplate tests using the labtech.com LT-4500. -

Page 18: Installation Qualification

Note It is very important that the person who installs the software has administrator rights on the computer. By default, all file types associated with LT-com for LT-4500 are stored in corresponding subdirectories in the following directory: ...\All Users\Documents\Labtech\LT-com 3.6.3... -

Page 19: Start Working With Lt-Com

3. Getting Started 3.6.4 Start Working with LT-com The main type of the user interface in LT-com is the wizard. Standard LT-com wizards represent workflow modules, which are step-by-step guides for performing complex procedures. Occasionally, menus are available in the heading bar. The Menu offers a conventional way of using the software: the relevant menu item is selected from the main menus. - Page 20 3. Getting Started Evaluate Results Wizard The Evaluate Results wizard is used to view the raw data and to evaluate the results. The evaluation parameters can be viewed and data can be re-evaluated. Attach Signature Wizard The Attach Signature wizard is used to sign method and workspace files. Create/Edit a Sample ID List Wizard The Create/Edit a Sample ID list wizard is used to create new and to edit existing sample ID lists.

-

Page 21: Com - Measurement Parameter Editor

3. Getting Started LT-com - Measurement Parameter Editor The Measurement Parameter Editor is used to set up workflows. Each workflow is easily created by dragging and dropping the process steps into a sequence according to the application. The application workflow is then visible to the user in the workflow pane. -

Page 22: Control Bar

Create a workflow either by double-clicking the selected program element or by dragging and dropping it into the workflow pane. The following program elements are available when using an LT-4500: Lab Ware Plate... - Page 23 3. Getting Started Independent Parts of Plate Independent parts of the plate can be selected: A second range of wells can be selected by pressing the Control key on the keyboard and dragging a frame over the wells to be selected. Measurements Absorbance The Absorbance program element is used to perform absorbance...

- Page 24 3. Getting Started Actions Shaking Select the Shaking program element if the plate is to be shaken, either before the measurement or between kinetic cycles. Enter the respective parameters: Duration Enter the duration of the shaking process. Intensity Enter the desired shaking mode. Amplitude and frequency are displayed when choosing the respective shaking mode.

- Page 25 3. Getting Started Kinetic Kinetic Cycle Use the program element Kinetic Cycle to perform several consecutive measurements, which may be executed in certain intervals. Enter the respective parameters: Cycles Number of cycles: Enter a number or click the up or down arrows for the number of actual measurement steps (2 –...

- Page 26 3. Getting Started Miscellaneous Comment Use the program element Comment to enter a remark or statement for the current measurement in the text field. User Request The User Request program element informs the operator of the instrument to execute a definite action during the workflow at a certain time. If for example the Move Plate program element is used to move the plate out to perform a certain action, then the entered text should inform the operator to perform these actions.

-

Page 27: Workflow Pane

3. Getting Started Incubation Enter the appropriate parameters for incubation: Incubation time Enter the total time (min. 5 s) 3.7.2 Workflow Pane The Workflow pane is the window, where the measurement script is visible and where parameters are defined and edited. There are two ways to insert a program element from the Control bar into the Workflow pane: •... -

Page 28: Info Pane

3. Getting Started Hierarchy of Elements The hierarchy of elements in the Workflow pane is as follows: Plate Part of Plate (Range) Any desired measurement step can be inserted directly after a plate or range element. Use Release and Indent to modify the sequence of execution of the single strip component. -

Page 29: Com - Defining Measurements

3. Getting Started LT-com - Defining Measurements The following chapter describes some examples to illustrate the definition of different measurements. 3.8.1 Defining Endpoint Measurements The following example describes an Absorbance Endpoint Measurement in all wells of a 96-well microplate. Select a 96-well microplate from the Plate definition drop-down list. By default, all wells of the 96-well microplate are chosen for measurement. -

Page 30: Defining Multilabel Measurements

3. Getting Started 3.8.2 Defining Multilabel Measurements The following example describes an Absorbance Multilabel Measurement in a defined range of a 96-well microplate (A1:E7). Three absorbance labels shall be measured. Select a 96-well microplate from the Plate definition drop-down list. By default, all wells of the 96-well microplate are chosen for measurement. -

Page 31: Defining Kinetic Measurements

3. Getting Started 3.8.3 Defining Kinetic Measurements The following example describes a kinetic measurement of a 96-well microplate. Select a 96-well microplate from the Plate definition drop-down list. Insert a Kinetic Cycle program element between the part of plate and the absorbance element. -

Page 32: Indenting And Releasing Program Elements

3. Getting Started 3.8.4 Indenting and Releasing Program Elements The decision to indent/release a program element will modify the workflow of the instrument during measurements. The actions of all program elements with the same indentation are performed sequentially. The only dependence between these program elements is that the next action starts directly after the previous action is finished. - Page 33 3. Getting Started Releasing the second Absorbance program element, so that it is aligned with the Kinetic Cycle element, changes the workflow. Select the second Absorbance program element and click the right mouse button. Select Release Strip from the context sensitive menu. The Workflow pane appears as shown in the following screenshot: In this workflow, an Absorbance kinetic measurement with 5 cycles is done for the first absorbance at 450 nm;...

-

Page 34: Optimizing For Best Performance

Make sure that the type of microplate used with the LT-4500 absorbance reader is suitable for the respective application. •... -

Page 35: Instrument Features

4.1.1 Microplate Shaking The LT-4500 is able to shake the microplate before it is measured. The microplate can also be shaken between each of the kinetic measurement cycles. Use LT-com to set the shaking mode. -

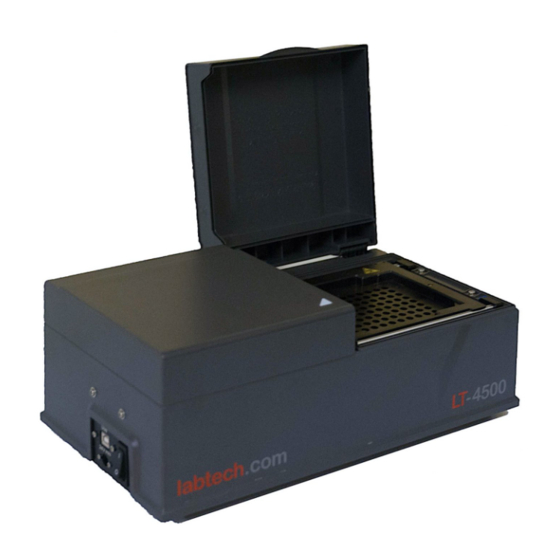

Page 36: Instrument Description

4. Instrument Features Instrument Description Status LED Microplate positioning Position of well A1 spring Plate transport The illustration above shows the components of the instrument. The status LED gives information of the status of the instrument: • Green blinking: instrument is not connected to LT-com •... - Page 37 4. Instrument Features On the left panel of the instrument the USB port, main power switch, and main power socket can be found. USB port Main power switch Main power socket The nameplate is attached to the bottom of the instrument. Example Name Plate Contents of the name plate (e.g.

-

Page 38: Filter Wheel Description

4. Instrument Features Filter Wheel Description The LT-4500 standard filter wheel is delivered with four narrow band interference filters that have a fixed wavelength (405, 450, 620, and 492 nm). It is possible to equip the filter wheel with up to 8 filters. For accessorily available filters please contact your local supplier. -

Page 39: Instrument Specifications

4. Instrument Features Instrument Specifications The tables below list the specifications for the LT-4500 absorbance reader. 4.4.1 General Specifications PARAMETERS CHARACTERISTICS Main power input Power supply: External power supply Basic instrument with AC adapter: 100-240 V AC, 50/60 Hz, max. 1.2 A (auto... -

Page 40: Measurement Specifications

4. Instrument Features 4.4.2 Measurement Specifications PARAMETERS CHARACTERISTICS Measurement time: single wavelength < 15 seconds dual wavelength < 20 seconds Wavelength range: Standard 400 - 750 nm Measurement range: 400 - 750 nm 0 - 4.000 OD Resolution: 0.0001 OD Accuracy: 450, 492 nm 0.000 - 2.000 OD ≤... -

Page 41: Microplates

Microplates All 96-well microplates with transparent bottom (flat, C-, U-, and V-shaped; including strip-well microplates) that are conform to the following standards can be used with the LT-4500 absorbance reader: ANSI/SBS 1-2004; ANSI/SBS 2-2004; ANSI/SBS 3-2004; ANSI/SBS 4-2004 CAUTION ONLY USE MICROPLATES WITHOUT LIDS AND DO NOT USE MICROPLATES HIGHER THAN 15.2 MM. -

Page 42: Available Option For Lt-4500

LIS Option – Handheld Barcode Scanner The LIS option (Laboratory Information System Option) is an additional option for LT-4500 instruments and allows reading of plate and sample IDs from compatible barcodes by using a handheld barcode scanner which is part of the LIS Option. -

Page 43: Instrument Accessories

Reading field 80 mm typical (3.150 inch) Max. resolution 0.13 mm (5.118 mil; 0.005 inch) Instrument Accessories The list below contains the available optional accessories for the LT-4500, which can be ordered additionally: • LIS Option - handheld barcode scanner •... -

Page 45: Quality Control

Self Check Procedure During the connection of the LT-4500 to the LT-com reader control software, motors and sensors are checked and plate carrier and filter wheel are initialized. Prior to each measurement a self check calibration procedure is performed to ensure that the instrument is working correctly and to calibrate the optical system. -

Page 46: Microplate Test

5. Quality Control 5.3.2 Microplate Test If the optical densities of the wells in the microplate are not consistent, the results obtained with this type of microplate will be influenced. This inconsistency can be checked by reading an empty microplate. The OD values obtained from the measurement of the empty microplate should be in a narrow range. -

Page 47: Instrument Linearity With Liquid Samples

5. Quality Control 5.3.4 Instrument Linearity with Liquid Samples The linearity for the instrument and application at the wavelength used can be checked by using a dilution series of a solution. The result depends on the purity of the dye used and the meniscus of the liquid in the wells. -

Page 49: Application Example

6. Application Example Application Example Introduction The LT-com example files provide LT-com methods and workspaces to introduce the software and to ease the user’s work with it. The example files for a quantitative and a qualitative ELISA assay are installed automatically upon installation of LT-com. - Page 50 6. Application Example Measurement and Evaluation Read plate at a wavelength of 492 nm, reference at 620 nm. Blank reader/plate on well A1. Concentrations of the Calibrators (Standards): Calibrator 1 5 UA/ml Calibrator 2 10 UA/ml Calibrator 3 20 UA/ml Calibrator 4 40 UA/ml Calibrator 5...

-

Page 51: Create A Method

6. Application Example 6.2.2 Create a Method In the Wizard List dialog box, select Create/edit a method and click OK. Click Continue on the Welcome page of the Create/edit a method wizard and the Select a file dialog box appears. Select New. Measurement Parameters Click Make Your Selection and the Measurement parameters page appears. - Page 52 6. Application Example On the Wavelength strip select 492 nm as Measurement wavelength and 620 nm as Reference wavelength. Continue Wizard by clicking Choose measurement parameters and the Plate layout window is displayed.

- Page 53 6. Application Example Design Layout Define the plate layout using the Well Assignment dialog box on the right side of the screen. In the Identifiers group box, select BL (Blank). In the Experimental group box the number 1 remains. In the Replicates group box, All is selected automatically. Click well A1, which is then marked with a red border.

- Page 54 6. Application Example All: All selected wells are defined as replicates. If an existing ID number for the samples and standards is chosen, the selected wells are then added as replicates to the existing replicates. With all other identifier types the selected wells are added as replicates to the existing replicates.

- Page 55 6. Application Example Transformations In the control bar on the left of the window select the next option, Add new transformation from the Transformed data item, to define blank reduction. A dialog box appears asking you if you want to define a blank reduction. Click Yes.

- Page 56 6. Application Example Concentration / Dilution / Reference Value Definition In the control bar select Conc., Dil., Ref.-values from the Method layout item to define the respective values as described in the test kit. Calibrator 1 5 UA/ml Calibrator 2 10 UA/ml Calibrator 3 20 UA/ml...

- Page 57 6. Application Example Standard Curve In the control bar click Standard curve from the Concentrations item to define the appropriate standard curve. The following is in the test kit description: After the blank correction, the optical densities (OD 492 - OD 620) are plotted versus the concentration.

- Page 58 6. Application Example On the Axis tab, define the labeling and the scaling of the axis as shown below: On the Graph tab, define the graph title, curves, font and graph display.

- Page 59 6. Application Example Define Cutoffs In the control bar select Cutoff definition from the Evaluate data item to define the limits for the qualitative evaluation. The test kit description contains the following instructions: Interpretation of the test results: IgM < 18 UA/ml Negative 18 UA/ml ≤...

- Page 60 6. Application Example Define QC Validations In the control bar, click QC Validations from the Evaluate data item. Validation criteria for the test must be defined, so that the validity of the test results is guaranteed. In this example the following requirement must be fulfilled: The calculated IgM-concentration of both negative controls must be under 8 UA/ml.

-

Page 61: Organize Printed Report

6. Application Example 6.2.3 Organize Printed Report In the control bar, click Printed report from the Data handling item. The following screen is displayed: On the Data selection tab, all available report data is contained in the Available data box. Using the Insert and Append buttons, data can be transferred into the Selected data box. - Page 62 6. Application Example Select Method layout/Layout in the Available data box and attach it as a matrix to the report by clicking Append. Then insert Blank reduction, Mean conc. (UA/ml) and Cutoff results into the matrix by selecting the corresponding items and clicking Insert.

- Page 63 6. Application Example Note Exported data should always contain the Layout or Sample ID List. Automated Data Handling In the control bar, select Automated data handling from the Data handling item. Select export to ASCII file, and view results after measurements. In LT-com, save workspace is selected by default and cannot be modified.

- Page 64 6. Application Example Save the Method Click Next to open the Save as window. Enter the method filename and complete any other field if appropriate. Filename A filename must be entered. A default filename is text field suggested automatically, but can be changed. File remarks Comments entered here will be saved and text field...

-

Page 65: Run The Method

6. Application Example 6.2.4 Run the Method If Run this method now is selected in the Save as dialog box of the Create/edit a method wizard, the Start Measurement Wizard/Start Measurement dialog box will appear after Save is clicked. In the Start Measurement dialog a default workspace name is assigned and can be altered by the user if desired. -

Page 66: Evaluate The Result

6. Application Example 6.2.5 Evaluate the Result Select Evaluate results to view and evaluate raw data. The evaluation parameters can be viewed and data can be re-evaluated. This section guides you through the Evaluate Results wizard using an example workspace file automatically installed upon installation of LT-com. In the Wizard List dialog box, click Evaluate results. - Page 67 6. Application Example Click in the well with the right mouse key and the context-sensitive menu appears: Selecting Summary the following window is displayed providing detailed information of the definition and the settings of the chosen well: Click Next in the plate layout window and the Save as dialog box appears, where you can enter a file name and remarks.

-

Page 68: Summary Of Definition Of Quantitative Elisa In Lt-Com

6. Application Example 6.2.6 Summary of Definition of Quantitative ELISA in LT-com 1. Subtract Blank value Definitions in LT-com Click on Add new transformation in the control bar and a window appears, asking if you want to define a Blank reduction. Click Yes and the Blank reduction formula is assigned automatically to all wells. -

Page 69: Cleaning, Maintenance, And Disposal

7. Cleaning, Maintenance, and Disposal Cleaning, Maintenance, and Disposal Introduction This chapter contains the following procedures: • Clean the instrument • Disinfect the instrument • Maintain the instrument • Insert or replace filters in the filter wheel • Disposal instructions WARNING BEFORE DOING ANY CLEANING OR MAINTENANCE REMOVE THE MICROPLATE. -

Page 70: Cleaning The Instrument

7. Cleaning, Maintenance, and Disposal Cleaning the Instrument WARNING THE CLEANING PROCEDURE SHOULD BE PERFORMED IN A WELL- VENTILATED ROOM BY AUTHORIZED TRAINED PERSONNEL WEARING DISPOSABLE GLOVES AND PROTECTIVE GLASSES AND CLOTHING. Clean the housing of the device and the plate transport only with a dry or moist cloth. -

Page 71: Disinfection Solutions

7. Cleaning, Maintenance, and Disposal 7.3.1 Disinfection Solutions The outer surfaces and the plate transport of the instrument should be disinfected using a disinfectant such as: • Microcide SQ • Decon 90 • 70 % Ethanol WARNING RISK OF FIRE AND EXPLOSION! ALCOHOLS, SUCH AS ETHANOL OR ISOPROPANOL, ARE FLAMMABLE AND WHEN IMPROPERLY HANDLED CAN LEAD TO EXPLOSIONS AND/OR FIRE. - Page 72 7. Cleaning, Maintenance, and Disposal Carefully apply the disinfectant solution on the plate transport according to the manufacturer’s Instructions for Use. Do not use too much disinfectant to prevent the solution flowing into the instrument or soiling the lenses when moving the plate transport into the device.

-

Page 73: Safety Certificate

7. Cleaning, Maintenance, and Disposal 10. Carefully apply the disinfectant solution on all outer surfaces of the instrument. 11. After the required contact time wipe the instrument using a soft paper towel moistened with a mild detergent or distilled water to remove all traces of the disinfectant. -

Page 74: Preventive Maintenance Plan For Lt-4500

It is recommended to replace the filters every 4 years. Filter Replacement and Installation The LT-4500 must be connected to LT-com in order to do a software guided filter insertion or replacement. If the connection is lost during the procedure, due to accidental interruption of the connection between the instrument to the computer, LT-com has to be terminated and the instrument has to be switched off. -

Page 75: Filter Switching Procedure

7. Cleaning, Maintenance, and Disposal 7.5.1 Filter Switching Procedure The filters of the standard filter wheel can be replaced or supplemented using the following procedure: In the Wizard list window, click Miscellaneous. Click Instrument control Click Define filter slides Click Filter switching to start the procedure. Remove any microplate from the plate transport! Tilt the instrument carefully backwards until it lies on the back side with the bottom facing towards you. - Page 76 7. Cleaning, Maintenance, and Disposal 10. When replacing a filter, use the filter assembly tool to remove the filter from the filter slot. Please contact your local supplier for the filter assembly tool and available filters. 11. Align the filter assembly tool with the notch of the stop-ring. Turn the tool and remove the stop-ring by pulling it out of the filter slot.

- Page 77 7. Cleaning, Maintenance, and Disposal 14. Place the stop-ring on the end of the filter assembly tool and turn it so it cannot slip off. 15. Using the filter assembly tool, push the stop-ring into the filter slot and press firmly into place. 16.

-

Page 78: Defining Filters

Follow laboratory procedures for biohazardous waste disposal according to national and local regulations. This chapter provides instructions on how to lawfully dispose of waste material accumulating in connection with the LT-4500. CAUTION OBSERVE ALL FEDERAL, STATE, AND LOCAL ENVIRONMENTAL REGULATIONS. -

Page 79: Disposal Of Operating Material

7.6.3 Disposal of Operating Material WARNING BIOLOGICAL HAZARDS CAN BE ASSOCIATED WITH THE WASTE MATERIAL (MICROPLATE) OF THE PROCESS RUN ON THE LT-4500 ABSORBANCE READER. TREAT THE USED MICROPLATE, OTHER DISPOSABLES, AND ALL SUBSTANCES USED IN ACCORDANCE WITH GOOD LABORATORY PRACTICE GUIDELINES. - Page 80 7. Cleaning, Maintenance, and Disposal Information for Treatment Facilities The LT-4500 consists of the following main components: • Poly-chlorinated biphenyl (PCB) • Plastics • Cable • Metals (Iron) • Nonferrous Metal (NFM) The instrument is compliant with the RoHS directive 2002/95/EC on the restriction of the use of certain hazardous substances in electrical and electronic equipment.

-

Page 81: Troubleshooting

8. Troubleshooting Troubleshooting Introduction The internal microprocessor controls and checks electronic functions as well as measurements, operations and results. If the microprocessor detects a fault or an incorrect operating procedure, an error message is displayed on the computer. 8.1.1 Table of Error Messages and Troubleshooting The following table gives a brief description of the error messages and the troubleshooting actions. -

Page 82: Definition Of 'Overflow

8. Troubleshooting Error Message Description Troubleshooting “Channel Low! Channel: Signal on channel Hardware problem: Electronic channel_nr, Minimum: channel_nr did not defect, broken fiber minimum, Maximum reach the expected maximum area between minimum and maximum “Invalid Wavelength! Filter wavelength is System error – report to customer Wavelength: wavelengthnm”... -

Page 83: Abbreviations, Trademarks, And Symbols

9. Abbreviations, Trademarks, and Symbols Abbreviations, Trademarks, and Symbols Abbreviations The following abbreviations are provided as a reference and may appear in the Instruction for Use. Ampere Alternating Current Analog Digital Converter American National Standards Institute/Society for ANSI/SBS Biomolecular Screening American Standard Code for Information ASCII Interchange... -

Page 84: Trademarks

The following product names and any registered and unregistered trademarks mentioned in this document are used for identification purposes only and remain the exclusive property of their respective owners: • LT-com, LT-4500 are trademarks of labtech.com, Uckfield, UK • Multicheck™ is a trademark of Tecan Austria GmbH ®... -

Page 85: Symbols

9. Abbreviations, Trademarks, and Symbols Symbols The following symbols appear on the instrument. Manufactured by Date of manufacture Conformité Européenne Read the Instructions for Use before operating the instrument In vitro diagnostic medical device Order number Serial Number USB label WEEE symbol RoHS symbol TÜV NRTL... -

Page 87: Index

Index Index Abbreviations ........... 83 Kinetic Condition ..........25 Absorbance ............. 23 Kinetic Control Bar .......... 25 Actions Control Bar .......... 24 Kinetic Cycle ............ 25 Application Example ........49 Kinetic Measurements ........31 Quantitative ELISA ........49 Lab Ware Control Bar........22 Cleaning............. - Page 88 Index Quality Control ..........45 Unpacking Unpacking and Inspection ......13 Unpacking Procedure ........13 User Profile ............12 Safety ..............9 User Request ........... 26 Safety Certificate ..........73 Self Check Procedure ........45 Shaking ............24, 35 Software ............17 Wait (Timer) .............