Summary of Contents for Toshiba ICC Multiprotocol Ethernet Interface ASD-G9ETH

- Page 1 ASD INTERFACE SERIES INDUSTRIAL CONTROL COMMUNICATIONS, INC. MULTIPROTOCOL ETHERNET INTERFACE FOR TOSHIBA G9 / VFAS1 ADJUSTABLE SPEED DRIVES August 2008 ICC #10639-2.100-000 ASD-G9ETH...

- Page 2 ASD-G9ETH Multiprotocol Ethernet Interface User's Manual Part Number 10639-2.100-000 Printed in U.S.A. ©2007-2008 Industrial Control Communications, Inc. All rights reserved OTICE SERS Industrial Control Communications, Inc. reserves the right to make changes and improvements to its products without providing notice. Industrial Control Communications, Inc.

-

Page 3: Usage Precautions

Usage Precautions Operating Environment • Please use the interface only when the ambient temperature of the environment into which the unit is installed is within the following specified temperature limits: -10 ∼ +50°C (+14 ∼ +122°F) Operation: -40 ∼ +85°C (-40 ∼ +185°F) Storage: •... -

Page 4: Table Of Contents

TABLE OF CONTENTS Introduction ...6 Features ...7 Precautions and Specifications ...9 Installation Precautions... 9 Maintenance Precautions ... 10 Inspection ... 11 Storage ... 11 Warranty ... 11 Disposal... 11 Environmental Specifications... 12 Interface Board Overview ...13 Installation ...14 Installation Procedure ... 14 Installing Multiple Option Cards ... - Page 5 10.4.5 Parameter List Filter ...29 10.4.6 Radix Selection...29 10.5 Profinet Tab...30 10.5.1 Information Window...30 10.5.2 I/O Data Configuration Arrays ...31 10.5.3 Device Identification and Configuration ...32 10.5.4 Submitting Changes ...32 10.6 BACnet Tab...33 10.6.1 Information Window...33 10.6.2 Device Identifiers ...34 10.6.3 Submitting Changes ...34 10.7...

- Page 6 Protocol-Specific Information ...61 13.1 Modbus/TCP... 61 13.1.1 Overview... 61 13.1.2 Coil & Discrete Input Mappings... 62 13.2 EtherNet/IP ... 64 13.2.1 Overview... 64 13.2.2 ODVA AC/DC Drive Profile ... 65 13.2.3 ControlLogix Examples: Setup... 68 13.2.4 ControlLogix Example: I/O Messaging... 70 13.2.5 Explicit Messaging Tag Reference...

-

Page 7: Introduction

1. Introduction Congratulations on your purchase of the ICC Multiprotocol Ethernet Interface for the Toshiba G9, H9, Q9 and VFAS1 families of Adjustable Speed Drives (ASDs). This interface allows information to be transferred seamlessly between the drive and several different Ethernet-based fieldbus networks with minimal configuration requirements. -

Page 8: Features

2. Features Ethernet Port IEEE 802.3 10/100BaseT Ethernet compliant. Shielded RJ45 connector accepts standard CAT5-type 8-conductor unshielded twisted-pair (UTP) patch cables. Supports multiple simultaneous protocols. Supported Protocols The interface currently provides server support for the following fieldbus protocols: • Modbus TCP •... - Page 9 Field-Upgradeable As new firmware becomes available, the interface can be upgraded in the field by the end-user. Refer to section 12 for more information. EtherNet/IP Data Access Options The EtherNet/IP protocol provides access to inverter data via explicit messaging, user-defined I/O assembly instances, and the ODVA AC/DC drive profile.

-

Page 10: Precautions And Specifications

3. Precautions and Specifications Rotating shafts and electrical equipment can be hazardous. Installation, operation, and maintenance of the ASD and interface board shall be performed by Qualified Personnel only. Qualified Personnel shall be: • Familiar with the construction and function of the ASD and interface board, the equipment being driven, and the hazards involved. -

Page 11: Maintenance Precautions

Ensure that the Charge LED is off prior to beginning maintenance. • Do Not attempt to disassemble, modify, or repair the interface board. Contact your ICC or Toshiba sales representative for repair or service information. • Turn the power on only after attaching the front cover and Do Not remove the front cover of the ASD when the power is on. -

Page 12: Inspection

Inspect the unit for shipping damage. • Check for loose, broken, damaged or missing parts. Report any discrepancies to your ICC or Toshiba sales representative. 3.4 Storage • Store the device in a well ventilated location (in its shipping carton, if possible). -

Page 13: Environmental Specifications

3.7 Environmental Specifications Item Operating Environment Operating Temperature Storage Temperature Relative Humidity Vibration Grounding Cooling Method Communication Speed The ASD-G9ETH interface is lead-free / RoHS-compliant. Specification Indoors, less than 1000m above sea level, do not expose to direct sunlight or corrosive / explosive gasses -10 ∼... -

Page 14: Interface Board Overview

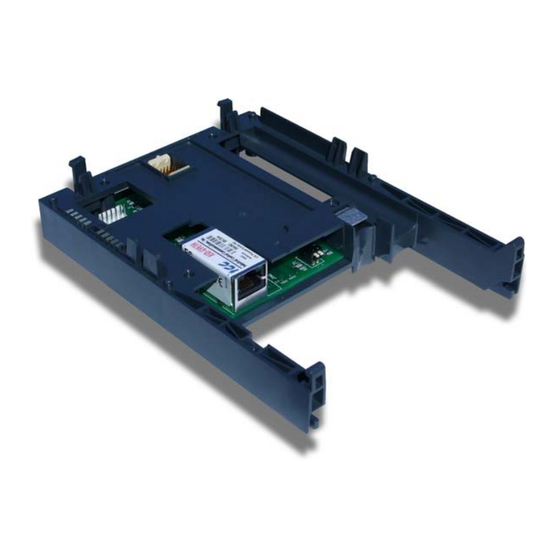

4. Interface Board Overview Mounting Tabs LEDs Note: The configuration switches are used for factory test only, and should remain in the OFF (up) position at all times. Drive Connector Configuration Switches Shielded RJ45 Ethernet Jack MAC ID Ground Plate... -

Page 15: Installation

5. Installation This interface card has been designed for quick and simple installation. The card is connected to the drive's control board via a 30-pin rectangular connector, and is mechanically supported via an integral housing that seamlessly mates with the drive’s enclosure. The only tool required for installation is a flat-blade screwdriver. - Page 16 Figure 2: Removing the Drive's Front Cover Install the interface card into the drive by inserting the tabs on the lower legs of the interface housing into the corresponding slots on the drive’s enclosure. Rotate the interface housing up and press it onto the drive enclosure’s mounting tabs, depressing firmly until the housing snaps into place (Figure 3).

-

Page 17: Installing Multiple Option Cards

OFF. Repeat steps 1 and 2 to remove all power from the drive. Then, verify all connections. Contact ICC or your local Toshiba representative for assistance if the problem persists. 5.2 Installing Multiple Option Cards When this communication interface is installed into a drive in conjunction with an I/O option card, the I/O option card must be installed first (adjacent to the drive’s enclosure), and the communication interface must be installed last... -

Page 18: Led Indicators

6. LED Indicators 6.1 Front Panel The interface board has 5 bicolor (red/green) LEDs that are visible through the ASD’s front cover (labeled 2.1 through 2.5). Interface Status EIP Module Status / Reserved EIP Network Status / Profinet Cnxn Status Ethernet Activity Heartbeat Interface Status: Normally solid... -

Page 19: Ethernet Jack

EIP Network Status / Profinet IO Connection Status: When the multi- protocol firmware image (with EtherNet/IP support) is loaded, this LED conforms to the prescribed “network status LED” behavior as dictated in the EtherNet/IP specification, Volume 2, Chapter 9. When the Profinet IO firmware image is loaded, this LED is on solid green when the controller has established a link with the interface board and is communicating with it. -

Page 20: Configuring The Ip Address

7. Configuring the IP Address Before you can access the interface from your web browser or begin using it as a part of your automation network, you must know its IP address. The interface comes from the factory configured to obtain an IP address dynamically (DHCP/BOOTP). -

Page 21: Via The Drive's Keypad

In the dialog that appears, select Manually configure network settings. Enter the desired IP Address, Subnet Mask, Default Gateway and case- sensitive system password (default is “icc”) in the appropriate boxes, then click Apply. A popup dialog box will prompt you to reboot. Click Reboot Device. Rebooting may require 30s or more to complete. -

Page 22: Using The Icc Finder Utility

8. Using the ICC Finder Utility The “ICC Finder” utility is a simple Windows PC program (just a single .exe file, no installations, DLL’s etc.), which when executed discovers all ICC communication interfaces on the current Ethernet subnet, regardless of whether or not their network parameters are currently compatible with the subnet upon which they reside. -

Page 23: Parameter Numbering

9. Parameter Numbering Inspection of the Toshiba ASD user’s manual reveals that the ASD’s parameters are organized as hexadecimal numbers ranging from F000 to FFFF. These parameters are made accessible to the interface board as “registers”, and are numerically remapped to present a more natural interface to the communications user. - Page 24 user’s manual. Similarly, when this user’s manual uses the term “register”, it will be referring to the decimal number as it is exposed to the network interface. Note that although 1500 total registers are available in the register space, not all of those registers have corresponding parameters that exist in the drive.

-

Page 25: Embedded Web Server

10. Embedded Web Server 10.1 Overview The interface contains an embedded web server (also known as an HTTP server), which allows users to access the drive’s internal data in a graphical manner with web browsers such as Microsoft Internet Explorer or Mozilla Firefox. -

Page 26: Authentication

unit is highlighted, or just directly enter the target unit’s IP address into the address (URL) field of your web browser. Refer to Figure 7 for a representative screenshot of the web server interface. In order to access the web server and view the parameter values, destination TCP ports 80 and 2000 must be accessible from the client computer. -

Page 27: Page Select Tabs

10.3 Page Select Tabs The web interface is subdivided into several different “tabs” of associated information, much the same as how folders in a filing cabinet are arranged. Refer to Figure 9. To change tabs, just click on the tab you wish to view. The title of the currently-selected tab is red. -

Page 28: Parameter Subgroup Selection List

parameter subgroups (if any) contained in that parameter group are displayed in the Parameter Subgroup Selection List (refer to section 10.4.3), and the corresponding parameters are displayed in the Parameter List (refer to section 10.4.4). The following parameter groups are available: All: All parameters are available (configuration, command and monitor... -

Page 29: Parameter List

10.4.4 Parameter List The bottom half of the Monitor tab contains the parameter list (refer to Figure 13). The parameters that are displayed in the list at any given time depend on the group/subgroup selected, as well as whether or not any filters have been applied (refer to section 10.4.5). -

Page 30: Parameter List Filter

10.4.5 Parameter List Filter A filter function provides Parameter List search capabilities. To use the filter function, simply type a word or portion of a word into the filter entry box and then click the “filter” button. Refer to Figure 14. The filter will then display only those parameters currently available in the Parameter List... -

Page 31: Profinet Tab

10.5 Profinet Tab This section is only applicable when the Profinet firmware is loaded onto the interface card. The Profinet tab provides for the configuration of the device on a Profinet network. Refer to Figure 16. Figure 16: Profinet Tab 10.5.1 Information Window Figure 17 shows the Information Window, which is located in the upper-left hand corner of the Profinet tab. -

Page 32: I/O Data Configuration Arrays

10.5.2 I/O Data Configuration Arrays The I/O data configuration arrays consist of two separate elements (refer to Figure 18.) The command register configuration defines the structure of the command data sent from the Profinet controller to the drive, and the status register configuration defines the structure of the status data sent from the drive back to the controller. -

Page 33: Device Identification And Configuration

10.5.3 Device Identification and Configuration There are several identification and configuration items available for setting various characteristics of the Profinet device. These items are shown in Figure 19 and are explained in further detail below. Figure 19: Profinet Device Identification and Configuration A Profinet device’s name (station name) must be unique across the entire Profinet network because it is used by controllers to uniquely identify Profinet devices. -

Page 34: Bacnet Tab

10.6 BACnet Tab The BACnet tab provides for the configuration of the device on a BACnet/IP network. Refer to Figure 21. Figure 21: BACnet Tab 10.6.1 Information Window Figure 22 shows the Information Window, which is located in the upper-right hand corner of the BACnet tab. -

Page 35: Device Identifiers

10.6.2 Device Identifiers A BACnet device’s name and ID (the Object_Name and Object_Identifier properties, respectively, of the Device Object) must be unique across the entire BACnet network because they are used to uniquely identify BACnet devices. The text entry boxes shown in Figure 23 are used to configure these unique device identifiers on every drive. -

Page 36: Config Tab

10.7 Config Tab The Config tab provides access to various configuration items. Refer to Figure Figure 25: Config Tab 10.7.1 Information Window Figure 26 shows the Information Window, which is located in the upper-right hand corner of the Config tab. This window displays various informational messages regarding the status of the configuration parameters (loading or submitting). -

Page 37: Drive Configuration Parameter Write Selection

If written to both RAM and EEPROM, then parameter value changes will be retained. When enabling writes to EEPROM, be sure to always observe Toshiba’s restrictions on the number of times a configuration parameter may be written to EEPROM before possible EEPROM damage occurs. -

Page 38: Timeout Configuration

10.7.4 Timeout Configuration The interface can be configured to perform a specific set of actions when network communications are lost. Support for this feature varies depending on the protocol: refer to the protocol-specific section of this manual for further information. There are two separate elements that comprise the timeout configuration (refer to Figure 29):... -

Page 39: Ip Address Configuration

10.7.5 IP Address Configuration Figure 30 shows the configuration items used to modify the IP address-related parameters. Modification of these settings is consistent with the technique used with the Finder utility (refer to section 7.1). Figure 30: IP Address Configuration 10.7.6 MAC Address Configuration Figure 31 shows the entry boxes that are used to view and/or modify... - Page 40 Note that because these configuration elements are read from the filesystem only when the interface card boots up, the act of submitting configuration changes will also reset the interface card. Please allow 30 seconds for the interface card to reboot, at which time it will then be operating with the recently- submitted configuration.

-

Page 41: Ethernet/Ip Tab

10.8 EtherNet/IP Tab The EtherNet/IP tab provides access to configuration items related to communication on an EtherNet/IP network. Refer to Figure 33. Figure 33: EtherNet/IP Tab 10.8.1 Information Window Figure 34 shows the Information Window, which is located in the upper-right hand corner of the EtherNet/IP tab. -

Page 42: Device Identification

10.8.2 Device Identification A text entry box is available which allows customization of the device’s name for identification on the EtherNet/IP network. This string is accessible as the “product name” attribute of the identity object. Refer to Figure 35. Figure 35: EtherNet/IP Device Identification 10.8.3 Run/Idle Flag Behavior EtherNet/IP clients (such as PLCs) have... -

Page 43: Class 1 (I/O) Data Configuration Arrays

10.8.4 Class 1 (I/O) Data Configuration Arrays The interface card supports two different types of EtherNet/IP class 1 (I/O) data transfer. One type is included with the implementation of the AC/DC drive profile, and requires no user configuration. The other type, however, is entirely user-configurable, and is utilized when the client opens a connection to the interface using assembly instances 100 and 150. -

Page 44: Submitting Changes

controller may request larger consumed and/or produced data sizes, but all unreferenced consumed data will be ignored, and all unreferenced produced data will contain dummy “0” values). The first word (two bytes) of consumed data will be written to register 1007 (command 1) and the second word will be written to register 1008 (frequency command). -

Page 45: Alarm Tab

10.9 Alarm Tab The Alarm tab provides a configurable mechanism by which the interface card can autonomously monitor any available drive register and send emails to up to four recipients when a certain condition is detected. The alarm conditions have both value and time constraints, and can be configured to retrigger at a fixed interval as long as the alarm condition continues to be satisfied. -

Page 46: Email Configuration

10.9.2 Email Configuration In order for an alarm trigger to successfully send a notification email, some network settings must first be configured properly (refer to Figure 41 and Figure 42.) DNS Servers: Enter the dotted- decimal IP addresses of the primary and secondary DNS servers which will be used to resolve the configured SMTP... -

Page 47: Alarm Configuration

SMTP Authentication: Some email servers require that clients wishing to send emails first authenticate themselves. If the email server in use requires authentication, then enter the user name and password as indicated in Figure 42. If the email server in use does not require authentication, then these entries can be disregarded. - Page 48 Register: Enter the drive register number that this alarm will continuously monitor. For example, the alarm displayed in Figure 45 is configured to monitor register 1302, which is “inverter status 1”. Figure 45: Alarm Configuration Box Logical Comparison: Choose a comparison operator which will be used to compare the current value of the indicated “Register”...

-

Page 49: Submitting Changes

for the alarm to be triggered. A time of 0 seconds means that just a single evaluation of “true” will immediately trigger the alarm. Send Additional Reminders While The Condition Remains True: If this check box is unchecked, then only one email transmission event will occur when an alarm condition is triggered: further email transmissions will not be attempted for this alarm unless the alarm condition is first evaluated as “false”... -

Page 50: Modbus Tab

10.10 Modbus Tab The Modbus tab provides access to configuration items related to communication on a Modbus TCP network. Refer to Figure 47. Figure 47: Modbus Tab 10.10.1 Information Window Figure 48 shows the Information Window, which is located in the upper-right hand corner of the Modbus tab. - Page 51 were desired to read the inverter’s status 1 word (register 1302), torque (register 1319) and output voltage (register 1306), this could be accomplished in two different ways: Implement three separate Modbus read transactions, each one reading one register only, or Implement one single Modbus read transaction, starting at register 1302 for a quantity of 18 registers.

-

Page 52: Submitting Changes

been remapped to register 2001, register 1024 (command 2 word) has been remapped to register 2002, register 1034 (torque command) has been remapped to register 2003, register 1302 (inverter status 1) has been remapped to register 2004, register 1319 (torque) has been remapped to register 2005, and register 1306 (output voltage) has been remapped to register 2006. -

Page 53: Interacting With The Filesystem

11. Interacting With the Filesystem The interface card’s on-board filesystem is used to store files for use by the application firmware. Currently, the application firmware’s main use of the filesystem is to store XML-encoded configuration files that dictate the characteristics of the various protocols. Each protocol that requires configuration will have its own XML file stored on the filesystem. -

Page 54: Initiating Ftp Via The Finder Utility

11.1 Initiating FTP via the Finder Utility After discovering all interface cards on the current subnet as described in section 8, select the target interface card and then click on the “Open FTP Interface” button. This will open the computer’s default FTP application, which could be Windows Explorer, a web browser, or a 3 -party FTP program (whatever the computer/operating system is configured for by default). -

Page 55: Using Ftp With Windows Explorer

11.2 Using FTP with Windows Explorer To use FTP with Microsoft Windows Explorer, first open either “Windows Explorer” or “My Computer”. Refer to Figure 53. Please note that the indicated procedure, prompts and capabilities outlined here can vary depending on such factors as the installed operating system, firewalls and service packs. - Page 56 Figure 55: FTP Authentication Windows Explorer will then display the filesystem’s contents (refer to Figure 56.) You can now perform normal file manipulation actions on the available files (cut, copy, paste, open, rename, drag-and-drop transfers etc.) in the same manner as though you were manipulating any traditional file stored on your computer’s hard drive.

-

Page 57: Using Ftp With A Windows Command Prompt

11.3 Using FTP with a Windows Command Prompt To use FTP with a Windows command (DOS) prompt, first open a command prompt by either selecting Start…All Programs…Accessories…Command Prompt, or by selecting Start…Run and typing “cmd” in the “Run” dialog. Once the command prompt opens, type “ftp” and the IP address of the target interface card. - Page 58 Figure 59: Copying a File from the Unit With "get" Command Figure 60: Copying a File to the Unit With "put" Command...

-

Page 59: Using Ftp With Core Ftp Le

11.4 Using FTP with Core FTP LE Core FTP LE (Lite) is a 3 -party FTP application that can be downloaded for free from http://www.coreftp.com. Core FTP is just one example of the various commercial and freeware FTP client applications available on the internet. After installing Core FTP LE, run the program. - Page 60 Like most 3 -party FTP client applications, Core FTP LE has a wide array of configuration and file management capabilities, which are beyond the scope of this manual. Refer to the program’s Help file for more detailed instructions. Figure 62: Core FTP in "Connected" State...

-

Page 61: Loading New Application Firmware

12. Loading New Application Firmware The interface card’s embedded firmware resides in flash memory that can be updated in the field. Firmware updates may be released for a variety of reasons, such as custom firmware implementations, firmware improvements and added functionality as a result of user requests. Additionally, it may be necessary to load different firmware onto the unit in order to support various protocols (such as Profinet I/O). -

Page 62: Protocol-Specific Information

13. Protocol-Specific Information This section will discuss topics that are specific to each of the supported protocols. 13.1 Modbus/TCP 13.1.1 Overview The interface card supports Schneider Electric’s Modbus TCP protocol, release 1.0. The interface is conformance class 0 and partial class 1 and class 2 compliant, and allows up to 8 simultaneous Modbus TCP client connections (sockets). -

Page 63: Coil & Discrete Input Mappings

particular open socket experiences no activity for more than the timeout time setting, then the interface assumes that the client or network has experienced some sort of unexpected problem, and will close that socket. • Because the socket timeout determination is performed on a per-socket basis, note that a certain degree of caution must be exercised when using the network timeout feature to avoid “nuisance”... - Page 64 Where “discrete” ∈[1…65535], “bit” ∈[0…15], and “%” is the modulus operator, which means that any fractional result (or “remainder”) is to be retained, with the integer value being discarded (i.e. it is the opposite of the “floor” function). For clarity, let’s use Equation 1 and Equation 2 in a calculation example. Say, for instance, that we are going to read coil #34.

-

Page 65: Ethernet/Ip

13.2 EtherNet/IP 13.2.1 Overview The EtherNet/IP protocol is an application-level protocol implemented on top of the Ethernet TCP/IP and UDP/IP layers. It shares its object model with ControlNet and DeviceNet through the common Control and Information Protocol (CIP). This protocol allows the transfer of data and I/O over Ethernet. EtherNet/IP incorporates both the TCP and UDP layers of Ethernet in the transmission of data. -

Page 66: Odva Ac/Dc Drive Profile

• Supports unconnected messages (UCMM), and up to 16 simultaneous class 1 (I/O) or class 3 (explicit) connections. • Assembly instances 100 and 150: if a register entry in the consumed data configuration array is 0, then any consumed data that corresponds to that location will be ignored. - Page 67 Output Instances 20 and 21 Detail Instance Byte Mapping Detail Run Fwd: forward rotation command (0=forward rotation off, 1=forward rotation on). Maps to inverter register 1007, bits 9 and 10. Run Fwd = 1 translates to inverter register 1007 bit 9 (direction) = 0 and bit 10 (run/stop) = 1. Note that if both the “Run Fwd”...

- Page 68 Input Instances 70 and 71 Detail Instance Byte From Mapping Detail Faulted: Inverter fault signal (0=not faulted, 1=faulted). Maps to inverter register 1302 (status 1 word), bit 0. Warning: This bit is not used (it is always 0). Running1 (FWD): Running forward status signal (0=not running forward, 1=running forward).

-

Page 69: Controllogix Examples: Setup

Speed Actual: Inverter operating speed in RPM. Maps to inverter register 1301 (output frequency). Because the inverter always provides its output frequency in units of Hz, the interface card applies a Hz-to-RPM conversion equation. The general Hz-to-RPM conversion equation is [output frequency x 120 / number of motor poles]. - Page 70 Assign the Ethernet module a name (we will use “EIP”) and an IP address, deselect “Open Module Properties”, and click OK. Figure 64: Identifying the New Module Download the configuration. Switch to online mode. Right click on the 1756-ENET/B module in the I/O Configuration and choose “Properties”.

-

Page 71: Controllogix Example: I/O Messaging

12) Apply the settings using the “Set” button. 13) You should now be able to confirm that the 1756-ENET/B module is configured properly by (for example) opening the module’s web interface in a web browser. 13.2.4 ControlLogix Example: I/O Messaging This section will demonstrate how to setup and use an EtherNet/IP I/O connection via vendor-specific assembly instances 100 &... - Page 72 In the “Connection Parameters” portion of the dialog box, enter the following information: Input: The Input Assembly is the collection of monitor data that is produced by the interface card and is received as an input to the PLC. Its structure is defined by the Produced Register Configuration as described in section 10.8.4.

- Page 73 You should now see the new module (named “ETHERNET-MODULE ASD_G9ETH”) in the 1756-ENET/B branch under the I/O Configuration in the controller organizer view. Right click on this new module, choose “Properties”, and select the Connection tab. Refer to Figure 68. Confirm the setting of the Requested Packet Interval (RPI).

-

Page 74: Explicit Messaging Tag Reference

solid green, indicating an “online/connected” state. By double-clicking “Controller Tags” in the project tree, it is possible to view the newly-added tags. Refer to Figure 71. The ASD_G9ETH:C configuration tag is unused, the ASD_G9ETH:I tag allows viewing of the input data, and the ASD_G9ETH:O tag allows modification of the output data. - Page 75 are written via the EtherNet/IP “data table write” service. Different tags exist for reading vs. writing. Any given register can be accessed with its own unique tag name, or an array tag can be used to access a group of registers with one PLC instruction. Tag names are generated according to the following structure: [action prefix][_reg_][register number] Where...

-

Page 76: Controllogix Example: Read A Register Block

as “rd_reg_1301[4]”, which starts at register 1301+4 = register 1305, the drive’s input voltage monitor register). In a similar manner, to write data to the interface card, the application PLC program must reference a “destination element” to which to start writing and the “number of elements”... - Page 77 Figure 73: Reduce the UnconnecteTimeout Value Collapse the “connection” tag again by clicking on the “-“ sign next to the tag name. Select the “Edit Tags” tab again. Create another new tag by entering “data_array” in the next blank Name field, and change its Data Type by typing in “INT[100]”...

- Page 78 The “Add Ladder Element” window appears. Select the “XIO” element in the Bit folder. Refer to Figure 75. Click OK. Figure 75: Adding an XIO Element Configure the MSG instruction. Edit the “Message Control” field on the MSG instruction to use the previously-created “connection”...

- Page 79 reading a total of 25 registers beginning at rd_reg_basic[10]. Offset 10 in the interface card’s rd_reg_basic root tag (which starts at register 1) refers to 1+10 = register 11 (deceleration time 1). If we wish, we could also use the tag name which references deceleration time 1 directly (rd_reg_11) to achieve the same results.

- Page 80 Figure 78: Selecting the Destination Element “Communication” tab settings (refer to Figure 79): Enter the Path to the interface card. A typical path is formatted as “Local_ENB,2,target_IP_address”, where: • Local_ENB is the name of the 1756-ENBx module in the local chassis (we named ours “EIP”...

- Page 81 If “Cache Connections” is enabled (checked), the connection remains open after transmission. If disabled (unchecked), the connection is opened before and closed after every transmission. For efficiency, it is recommended to enable “Cache Connections”. Click “OK” to close the MSG Configuration dialog. At this stage, MainRoutine should look like Figure 80.

- Page 82 The program is now complete. Refer to Figure 82. Figure 82: Complete Program Save, download and run the program. To view the values of the registers being read from the interface card, double-click “Controller Tags” in the controller organizer view. Figure 83: Viewing the Register Values Select the “Monitor Tags”...

-

Page 83: Controllogix Example: Read A Single Register

Expand the data_array tag. Refer to Figure 83. 25 register values starting at register #11 are being continuously read from the interface card and placed in the 25 sequential offsets of data_array starting at the 11 can see that data_array[10] (deceleration time #1) has a value of 100 (10.0s), data_array[11] (maximum frequency) has a value of 8000 (80.00Hz) etc. -

Page 84: Controllogix Example: Reading And Writing

Figure 85: Reading Via Multiple MSG Instructions 13.2.9 ControlLogix Example: Reading and Writing Often times, applications may need to both read data from and write data to the drive. At a minimum, this will require two MSG instructions and two message controller tags. - Page 85 Figure 86: Reading and Writing via MSG Instructions Figure 87: MSG Configuration for Writing...

-

Page 86: Pccc

13.3 PCCC Ethernet-enabled Allen-Bradley legacy PLCs (such as the PLC5E and SLC- 5/05 series) use a protocol called PCCC (Programmable Controller Communication Commands) to communicate over the Ethernet network. The interface card supports PCCC for direct connectivity to these PLCs. If a connection timeout or socket-level error occurs, the driver will trigger a timeout event as described in section 10.7.4. -

Page 87: Slc-5/05 Example: Read A Register Block

N50 is targeted for writing, the written data is disseminated to the drive’s registers according to the definition contained in the EtherNet/IP consumed register configuration array. By appropriate configuration of the EtherNet/IP consumed and produced register configuration arrays, therefore, bulk access to non-contiguous but frequently-used drive registers can be conveniently provided by performing only one read and/or write instruction targeting file N50. - Page 88 Figure 88: Creating a Control File Follow the same procedure to create a data file. This file will be used to store the incoming data read from the interface card. Enter a file number (e.g. 18), set the type to “Integer”, enter a descriptive name (e.g.

- Page 89 Add a MSG instruction to the program. If not already visible, double-click “LAD2” under Project…Program Files in the controller organizer view to bring up the ladder logic program. Right click on the default rung number on the left-hand side of the LAD2 window and select “Insert Rung”.

- Page 90 Figure 91: XIO Instruction Selection Configure the MSG instruction. Set the “Read/Write” field to “Read”, “Target Device” field to “PLC5”, “Local/Remote” field to “Local”, and “Control Block” to “N20:0”. Upon hitting the <ENTER> key while in the “Control Block” entry box, the MSG Properties dialog box should appear (or it can be opened by clicking on the “Setup Screen”...

- Page 91 In this example, we will be reading a total of 25 registers beginning at N10:11 (register 11, the drive’s “deceleration time 1” parameter). To configure this, under “This Controller” set the “Data Table Address” field to N18:11, set the “Size in Elements field” to 25, and set the “Channel”...

- Page 92 causes the MSG instruction to automatically retrigger itself when it completes. While this is acceptable for the purposes of this example, it can produce high network utilization. In actual practice, it may be desirable to incorporate additional logic elements to allow triggering the MSG instruction at a specific rate or under specific conditions.

-

Page 93: Slc-5/05 Example: Read A Single Register

13.3.3 SLC-5/05 Example: Read a Single Register The configuration and execution for reading a single register is in general identical to that required for reading a block of registers as detailed in section 13.3.2. The only difference is in the configuration of the MSG instruction. Figure 97 shows an example MSG instruction’s General tab, which will read a single element (N24:2, which corresponds to the drive’s “inverter status 1”... -

Page 94: Slc-5/05 Example: Reading And Writing

Figure 98: Reading Via Multiple MSG Instructions 13.3.5 SLC-5/05 Example: Reading and Writing Often times, applications may need to both read data from and write data to the drive. At a minimum, this will require two MSG instructions and two message control files. - Page 95 Figure 99: Reading and Writing via MSG Instructions Figure 100: MSG Configuration for Writing...

-

Page 96: Bacnet

Applications Software Version: V2.100 Firmware Revision: BACnet Protocol Revision: Product Description: The Toshiba G9/AS1 is an advanced inverter featuring reduced high- frequency noise, reduced harmonics, and high-precision and high- speed torque control with or without sensors. BACnet Standard Device Profile (Annex L):... - Page 97 Segmented responses supported Standard Object Types Supported: See “Object Types/Property Support Table”. Data Link Layer Options: BACnet IP, (Annex J) BACnet IP, (Annex J), Foreign Device ISO 8802-3, Ethernet (Clause 7) ANSI/ATA 878.1, 2.5 Mb. ARCNET (Clause 8) ANSI/ATA 878.1, RS-485 ARCNET (Clause 8), baud rate(s) ______ MS/TP master (Clause 9), baud rate(s): 9600, 19200, 38400, 76800 MS/TP slave (Clause 9), baud rate(s): ______ Point-To-Point, EIA 232 (Clause 10), baud rate(s): ______...

- Page 98 Datatypes Supported: The following table summarizes the datatypes that are accepted (in the case of a write property service) and returned (in the case of a read property service) when targeting the present value property of each supported object type. Object Type Read Property Analog Output...

- Page 99 Object Types/Property Support Table The following table summarizes the Object Types/Properties supported. Property Object Identifier Object Name Object Type System Status Vendor Name Vendor Identifier Model Name Firmware Revision Appl Software Revision Protocol Version Protocol Revision Services Supported Object Types Supported Object List Max APDU Length Segmentation Support...

-

Page 100: Supported Objects

13.4.3 Supported Objects Binary Input Object Instance Summary Instance Object Name RUN_STOP_STATUS FWD_REV_STATUS F_PIT_STATUS R_PIT_STATUS ST_PIT_STATUS RES_PIT_STATUS S1_PIT_STATUS S2_PIT_STATUS S3_PIT_STATUS BI10 S4_PIT_STATUS BI11 OUT1_POT_STATUS BI12 OUT2_POT_STATUS BI13 FL_POT_STATUS Description Run/stop status Forward/reverse status "F" programmable input terminal status "R" programmable input terminal status "ST"... - Page 101 Binary Output Object Instance Summary Instance Object Name RUN_STOP_CMD FWD_REV_SEL EMERGENCY_OFF FAULT_RESET FEEDBACK_CTRL_SEL FREQ_PRIORITY COMMAND_PRIORITY DATA_OUT1_TERMINAL DATA_OUT2_TERMINAL BO10 DATA_OUT3_TERMINAL Analog Input Object Instance Summary Instance ID Object Name OUTPUT_FREQ LOAD_CURRENT OUTPUT_VOLTAGE INPUT_POWER_CONSUME Input power RR_ANALOG_INPUT VI_II_ANALOG_INPUT RX_ANALOG_INPUT TRIP_CODE Analog Output Object Instance Summary Instance ID Object Name FREQ_CMD_REG...

-

Page 102: Supported Object Details

13.4.4 Supported Object Details Binary Input Objects BI1 ...Indicates whether the drive is running or stopped. ASD parameter FE01, bit#10. BI2 ...Indicates whether the drive is running in the forward or reverse direction. ASD parameter FE01, bit #9. BI3 ...Indicates the status of the "F" programmable input terminal. ASD parameter FE06, bit#0. - Page 103 (BO1, BO2, and BO5) from the interface card to be used by the drive without having to explicitly set the Command Mode parameter. Refer to the Toshiba documentation regarding "Command Mode and Frequency Mode Control" for detailed information pertaining to the command source hierarchy and the use of overrides.

- Page 104 AI6 ...Similar to AI5, this object indicates the signal level currently being applied to the ASD's VI/II analog input terminal. ASD parameter FE36. AI7 ...Similar to AI5, this object indicates the signal level currently being applied to the ASD's RX analog input terminal. ASD parameter FE37. AI8 ...Indicates the present fault code.

-

Page 105: Profinet Io

13.5 Profinet IO • Up to 8 command registers can be sent to the drive, and up to 32 status registers can be retrieved from the drive. • A total of 84 modules are available for selection by the controller. Refer to the GSDML file for specific module information. - Page 106 INDUSTRIAL CONTROL COMMUNICATIONS, INC. Madison Office 1600 Aspen Commons, Suite 210 Middleton, WI USA 53562-4720 Tel: [608] 831-1255 Fax: [608] 831-2045 http://www.iccdesigns.com Houston Office 12300 Dundee Court, Suite 212 Cypress, TX USA 77429-8364 Printed in U.S.A...