Hitachi AirCore 700 Operation Installation Maintenance Manual

Single split inverter series indoor unit

Hide thumbs

Also See for AirCore 700:

- Operation installation maintenance manual (40 pages) ,

- Installation & maintenance manual (28 pages) ,

- Installation & maintenance manual (52 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hitachi AirCore 700

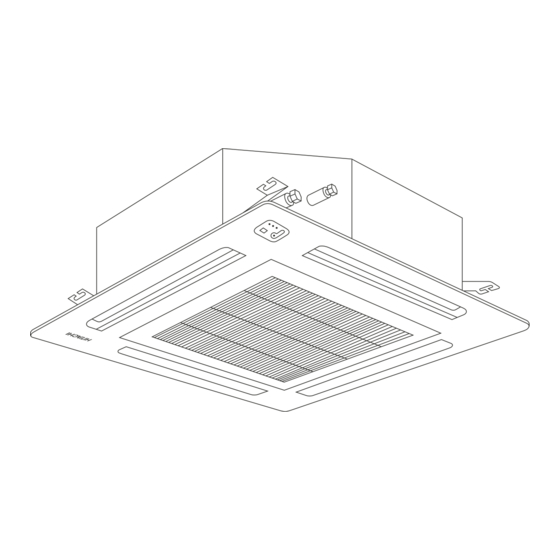

- Page 1 – OPERATION INSTALLATION & MAINTENANCE MANUAL – SINGLE SPLIT INVERTER SERIES INDOOR UNITS MODELS 4-WAY CASSETTE TYPE PCI-2.0UFA1NQ PCI-2.5UFA1NQ PCI-3.0UFA1NQ PCI-4.0UFA1NQ PCI-5.0UFA1NQ PCI-6.0UFA1NQ PCI-6.5UFA1NQ EN INSTRUCTION MANUAL Scan the code to get the electronic manual. P02133Q...

- Page 3 IMPORTANT NOTICE • Hitachi pursues a policy of continuous improvement in design and performance of products. The right is therefore reserved to vary specifications without notice. • Hitachi cannot anticipate every possible circumstance that might involve a potential hazard. •...

- Page 4 Please contact your local agent, as the occasion arises. Hitachi’s liability shall not cover defects arising from the alteration performed by a customer without Hitachi’s consent in a written form.

-

Page 5: Table Of Contents

Table of Contents 1. Safety Summary ............................1 2. Name of Parts ...............................10 3. Indoor Unit Installation ..........................10 3.1 Unit Installation ............................11 4. Refrigerant Piping ............................14 4.1 Piping Connection ..........................14 5. Drain Piping ..............................15 5.1 General Information ..........................15 5.2 Drain Pipe Connection ...........................16 6. -

Page 6: Safety Summary

DANGER • Hitachi is not able to foresee all the circumstances which may result in a potential danger. • Do not pour water in the indoor or outdoor unit. These products are fitted with electric components. - Page 7 1. Safety Summary WARNING • Only qualified personnel licensed or certified in their jurisdiction must carry out the installation work. Installation must be done in accordance with this installation manual. Improper installation may result in water leakage, electric shock, or fire. •...

- Page 8 • This air conditioner has been designed for standard air conditioning for human beings. For use in other applications, please contact your Hitachi dealer or service contractor. • The air conditioning system should only be installed by qualified personnel, with the necessary resources, tools and equipment, who are familiar with the safety procedures required to successfully carry out the installation.

- Page 9 1. Safety Summary • Do not install the unit in places where silicon gas is present. Any silicon gas deposited on the surface of the heat exchanger will repel water. As a result, the condensate water will splash out of the collection tray and into the electrical box.

- Page 10 1. Safety Summary required. • Field-made refrigerant joints indoors shall be tightness tested. The test method shall have a sensitivity of 5 grams per year of refrigerant or better under a pressure of at least 0,25 times the maximum allowable pressure. No leak shall be detected; Mechanical connections shall be accessible for maintenance purposes.

- Page 11 1. Safety Summary or vapour being present while the work is being performed. • All maintenance staff and others working in the local area shall be instructed on the nature of work being carried out. Work in confined spaces shall be avoided. •...

- Page 12 1. Safety Summary aging or continual vibration from sources such as compressors or fans. • Under no circumstances shall potential sources of ignition be used in the searching for or detection of refrigerant leaks. A halide torch (or any other detector using a naked flame) shall not be used. •...

- Page 13 1. Safety Summary (c) the recovery process is supervised at all times by a competent person; (d) recovery equipment and cylinders conform to the appropriate standards. ○ Pump down refrigerant system, if possible. ○ If a vacuum is not possible, make a manifold so that refrigerant can be removed from various parts of the system.

- Page 14 1. Safety Summary • Only use tools for R32, such as a gauge manifold, charge hose, gas leak detector, reverse flow check valve, refrigerant charge base, vacuum gauge, or refrigerant recovery equipment. • If the conventional refrigerant and refrigerator oil are mixed in R32, the refrigerant may deteriorate. •...

-

Page 15: Name Of Parts

2. Name of Parts 2. Name of Parts Item. Part Name Unit : mm Fan Motor Heat Exchanger Distributor Strainer Protective Cover(PCI(4.0-6.5) only) Electrical Box Refrigerant Gas Pipe Connection Refrigerant Liquid Pipe Connection Drain Pipe Connection Drain Discharge Mechanism Float Switch Drain Pan Rubber Plug for Drain Air Panel PHKF160PAQ1... -

Page 16: Unit Installation

3. Indoor Unit Installation • Check to ensure that the ceiling slab is strong enough. If not strong enough, the indoor unit may fall down on you. • Do not install the indoor units in a machinery shop or kitchen where vapor from oil or mist flows to the indoor units. - Page 17 3. Indoor Unit Installation 3. Check space between ceiling and false ceiling is enough as indicated below. 4. Check the ceiling surface is flat for the air panel installation work. Unit (HP) A(mm) 2.0 to 3.0 4.0 to 6.5 5. Check down slope Pitch of Drain Piping is following the specifications indicated in chapter “5. Drain Piping”.

- Page 18 3. Indoor Unit Installation • Consider piping connection side before lifting indoor unit . • Lift the indoor unit by hoist and do not put any force on the drain pan. • Secure the indoor unit using the nuts and washers. Suspension bolt Suspension bracket...

-

Page 19: Refrigerant Piping

4. Refrigerant Piping Tighten the nuts of the suspension brackets after the adjustment is completed. Apply LOCK-TIGHT paint to the bolts and nuts in order to prevent them from loosening. If not done, abnormal noises or sounds may occur and the indoor unit may come loose. 4. -

Page 20: Drain Piping

5. Drain Piping 5. Drain Piping 5.1 General Information INCORRECT CORRECT CAUTION • Do not create an upper-slope or rise for the drain piping, since drain water will flow back to the unit and leakage to the room will occur when the unit operation is stopped. •... -

Page 21: Drain Pipe Connection

5. Drain Piping 5.2 Drain Pipe Connection 1. The position of the drain pipe connection is shown below. 2. Prepare a polyvinyl chloride pipe with a 32mm outer diameter. 3. Fasten the tubing to the drain hose with an adhesive and the factory-supplied clamp. 4. -

Page 22: Electrical Wiring

6. Electrical Wiring 6. Electrical Wiring 6.1 General Information DANGER • Turn OFF the main power switch to the indoor unit and the outdoor unit and wait for more than 10 minutes before electrical wiring work or a periodical check is performed. •... -

Page 23: Electrical Wiring Connection For Indoor Unit

6. Electrical Wiring 6.2 Electrical Wiring Connection for Indoor Unit 1. The electrical wiring connection for the indoor unit is shown below. cable controller cable 2. Remove the electrical box cover (1 screw). 3. Loosen two (2) screws for the wiring support plate. 4. -

Page 24: Settings Of Dip Switches

6. Electrical Wiring 6.3 Settings of Dip Switches Quantity and position of dip switches DSW4 DSW9 DSW5 DSW6 DSW3 DSW7 CAUTION • Before setting dips switches, firstly turn off power source and set the position of the dips switches. If the switches are set without turning off the power source, the contents of the setting are invalid. - Page 25 6. Electrical Wiring DSW5: refrigerant cycle No. setting Setting is required DSW5 Factory setting: DSW5 can be set from 0 to 63. DSW6: unit No. setting, low air volume setting Setting is required. DSW6 (1st , 2nd digit) Unit number setting air volume setting DSW6 (6th digit) Low Set the position...

-

Page 26: Remote Controller Operation

7. Remote Controller Operation DSW9: Iconic panel setting Iconic panle is an accessory part. DSW9(3rd digit) Iconic Panel Setting Refer to the right picture for the setting. Set the position Before delivery, the setting of the 3rd digit is “0”. When installing iconic panel, the setting is changed to be “1”. - Page 27 8. Installation of Optional Air Panel PHKF160PAQ1 Removing air intake grille from air panel 1. Push both ends of knobs at the air inlet grille toward the arrow direction, open the air inlet grille until the angle of approximately 45° from the air panel surface. After lifting the air inlet grille keeping it inclined, draw the air inlet grille forward.

- Page 28 8. Installation of Optional Air Panel PHKF160PAQ1 5. Tighten the long screws until touching the stopper to the fixing plate. Check to ensure that the distance between the fixing plate undersurface and the corner panel undersurface is 26mm. 6. When tightening the long screws to prevent air leakage and to be no gap between the false ceiling surface and the indoor unit, the inner circumference of the air panel (the position to attach the air inlet grille) may be slightly deformed.

-

Page 29: Wiring Connection For Air Panel

9. Maintenance 8.3 Wiring Connection for Air Panel 1. The following connectors are used in the air panel. Remove the tape fixing the wiring connectors on the air panel and pull out them as shown in the figure below. Connect them with the wiring connectors on the indoor unit. -

Page 30: Clean The Filter

9. Maintenance 9.2 Clean the Filter Clean the air filter according to the following steps. 1. Use a vacuum cleaner or let water flow onto the air filter to removing the dirt from the air filter. CAUTION • Do not use hot water higher than approximately 40 2. - Page 31 MEMO...

- Page 32 Wire Harness 1184258 Hitachi-Johnson Controls Air Conditioning, Inc. Add: 1-16-1, Kaigan Minato-ku, Tokyo, Japan Specifications in this catalogue are subject to change without notice, in order that Hitachi-Johnson Controls may bring the latest innovations to customers. 2023.10 Printed in China...